Prices plus VAT plus shipping costs of 4,95 € to GER (incl. VAT)

Delivery time 5 Workdays to NL, BE, AT (GER -1 workdays)

| A - Measuring element: | ||

| B - Connection Type: | ||

| E - Material connection cable: | ||

| F - Length connection cable: | ||

| G - Connector: | ||

| H - Bend protection: | ||

| Quantity: |

- Order number: 803551-1011

Advantages

- We are ready to deliver: All information here

- Advice directly from experts

- Quality directly from the manufacturer

- Long-term stable temperature probes over years

- B2B customers welcome: All information here

Our employee will be happy to help you:

Julian Mäntele

Tel.: +49 (0)7653 96 59 771

E-Mail: jmaentele@testo-sensor.de

The cable probe with tapered measuring tip uses a protection sleeve that tapers from a diameter of 6 mm to a diameter of 3 mm. This allows it to be used at smaller measuring points, achieves a fast response time and is waterproof. (IP67)

Here you can find our downloads for the Cable probe tapered with PVC cable

Cable probe - General Information | |||||||||||||||||||

| Measuring range | -30 °C to +105 °C depending on sensor Type and connection cable | ||||||||||||||||||

| Perm. °C range cable | -30 °C to +105 °C | ||||||||||||||||||

| Accuracy | depending on sensor Type | ||||||||||||||||||

| Response time | t50: ≤ 1 s | t63: ≤ 1,5 s | t90: ≤ 2 s * | ||||||||||||||||||

| Pull-out force | ≥ 30 N | ||||||||||||||||||

| * Medium1: Air (25 °C) | Medium2: Water (60°C) | Flow velocity: 0.2 m/s | Measuring element: Pt100 | More information about response time measurement here | |||||||||||||||||||

Cable probe - Supply and output | |||||||||||||||||||

| Max. measurement current | max. 1 mA | ||||||||||||||||||

| Supply voltage | approx. 5 V depending on measurement current | ||||||||||||||||||

| Measurement signal | passive (resistance value) | ||||||||||||||||||

Cable probe - Ambient conditions | |||||||||||||||||||

| Protection class | IP67 according DIN 60529 | ||||||||||||||||||

| Humidity and moisture condensation resistance | according to application-specific qualification | ||||||||||||||||||

Cable probe - Certificates and Standards | |||||||||||||||||||

| Standards | DIN EN 61326-1:2013 | DIN EN IEC 63000:2019-05 | ||||||||||||||||||

| Directive | RoHS 2011/65/EU | 2014/30/EU | ||||||||||||||||||

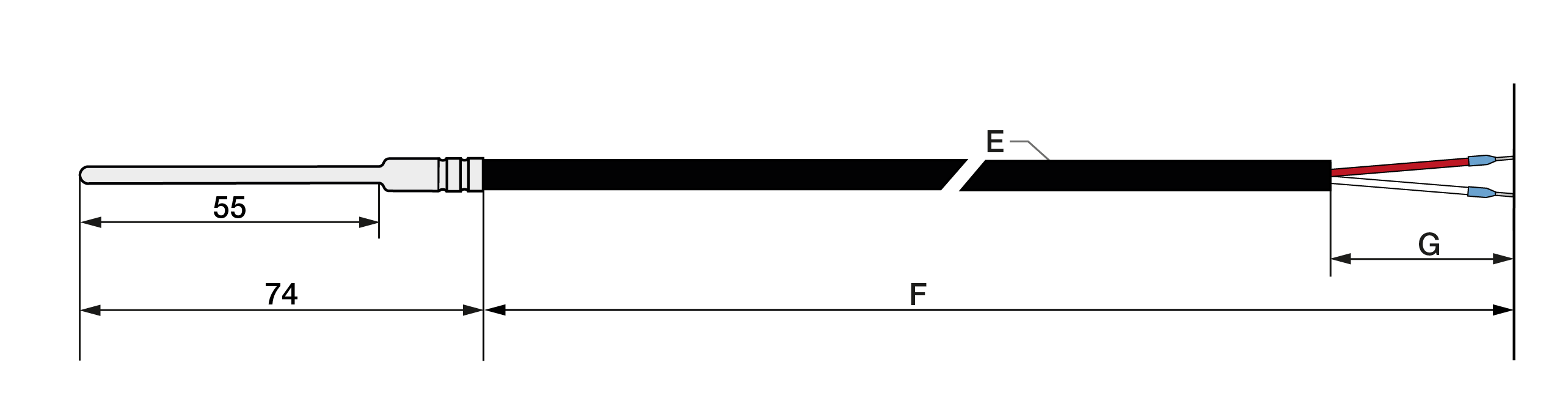

Cable probe - Technical Drawing | |||||||||||||||||||

| |||||||||||||||||||

| A - Measuring element | |||||||||||||||||||

| B - Connection Type | |||||||||||||||||||

| E - Material connection cable | |||||||||||||||||||

| |||||||||||||||||||

| F - Length connection cable | |||||||||||||||||||

| H - Bend protection | |||||||||||||||||||

| |||||||||||||||||||

| G - Connector | |||||||||||||||||||

| All dimensions in mm | |||||||||||||||||||

Cable probe - Measuring element | |||||||||||||||||||

| Measuring element | Perm. range °C | Accuracy / Tolerance resistance | |||||||||||||||||

| Pt100 | -50 °C to +400 °C | Class B dT = ±(0,30 °C + 0,005|t|)1} | |||||||||||||||||

| Pt100 | -50 °C to +300 °C | Class A dT = ±(0,15 °C + 0,002|t|)1} | |||||||||||||||||

| Pt100 | -50 °C to +200 °C | 1/3 Class B dT = ±(1/3 · (0,30 °C + 0,005|t|))1} | |||||||||||||||||

| Pt100 | ±0 °C to +100 °C | 1/10 Class B dT = ±(1/10 · (0,30 °C + 0,005|t|))1} | |||||||||||||||||

| Pt500 | -70 °C to +500 °C | Class B dT = ±(0,30 °C + 0,005|t|)1} | |||||||||||||||||

| Pt1000 | -50 °C to +400 °C | Class B dT = ±(0,30 °C + 0,005|t|)1} | |||||||||||||||||

| Pt1000 | -50 °C to +300 °C | Class A dT = ±(0,15 °C + 0,002|t|)1} | |||||||||||||||||

| NTC 5 kOhm | -40 °C to +150 °C | R25 = 5 KOhm ±1 % | |||||||||||||||||

| 1} according to IEC 751 / EN 60751 | Please note that the measuring range depends on the measuring element and the connection cable. | |||||||||||||||||||

Cable probe - Possible connections | |||||||||||||||||||

| Measuring element | 2W | 3W | 4W | ||||||||||||||||

| NTC | |||||||||||||||||||

| Pt | |||||||||||||||||||

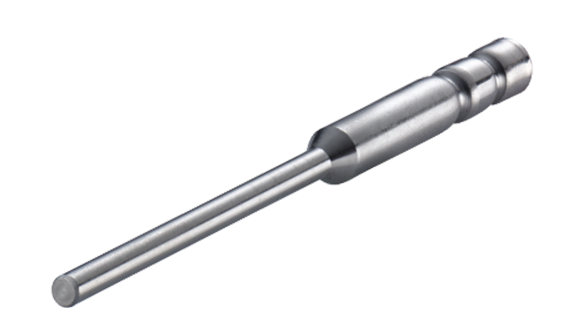

Cable probe - Protection sleeve | |||||||||||||||||||

| Material | Stainless steel 1.4404 | 316L | ||||||||||||||||||

| Diameter (mm)1} | 3 / 6 |  | |||||||||||||||||

| Length (mm) | 55,0 / 74 | ||||||||||||||||||

| 1} Tolerance ± 0,1 mm | |||||||||||||||||||

Cable probe - Material connection cable | |||||||||||||||||||

| Color: black, Perm. range °C: -30 to +105 | |||||||||||||||||||

| Material (Outside / Inside) | Ø Outside (mm) | Cross section (mm²)2} | Color strand | Ω / m1} | ||||||||||||||

| PVC / PVC | 4,8 ± 0,2 | 2 x 0,22 | rd, wt | 0,07 | |||||||||||||||

| PVC / PVC | 4,8 ± 0,2 | 3 x 0,22 | rd, wt, rd | 0,07 | |||||||||||||||

| PVC / PVC | 4,8 ± 0,2 | 4 x 0,22 | rd, wt, rd, wt | 0,07 | |||||||||||||||

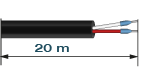

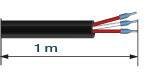

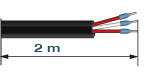

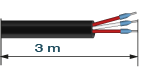

| Length (m) | 1, 2, 3, 4, 5, 10, 15, 20 | ||||||||||||||||||

| Insulation resistance: ≥ 100 MOhm at min. 100 VDC | Cable available as accessory | 1} per single strand | 2} Tolerance ± 0,03 mm² | |||||||||||||||||||

Cable probe - Connector | |||||||||||||||||||

| Insulated end ferrules (50 mm) | |||||||||||||||||||

Cable probe - Bend protection | |||||||||||||||||||

| Version | Without (Standard), Metal bend protection | ||||||||||||||||||

| Length (mm) | 50 | ||||||||||||||||||

| Material | Stainless steel spring 1.4310 | SUS 302 | ||||||||||||||||||

Cable probe - Delivery | |||||||||||||||||||

| Assembly instructions | by using compression fitting or immersion sleeve | ||||||||||||||||||

| Delivery and Packaging | Probe, seperatly packaged in PE bag | ||||||||||||||||||

| Matching accessories | Immersion sleeve, Heat-conducting paste, Compression fitting, Quick-release strap | ||||||||||||||||||

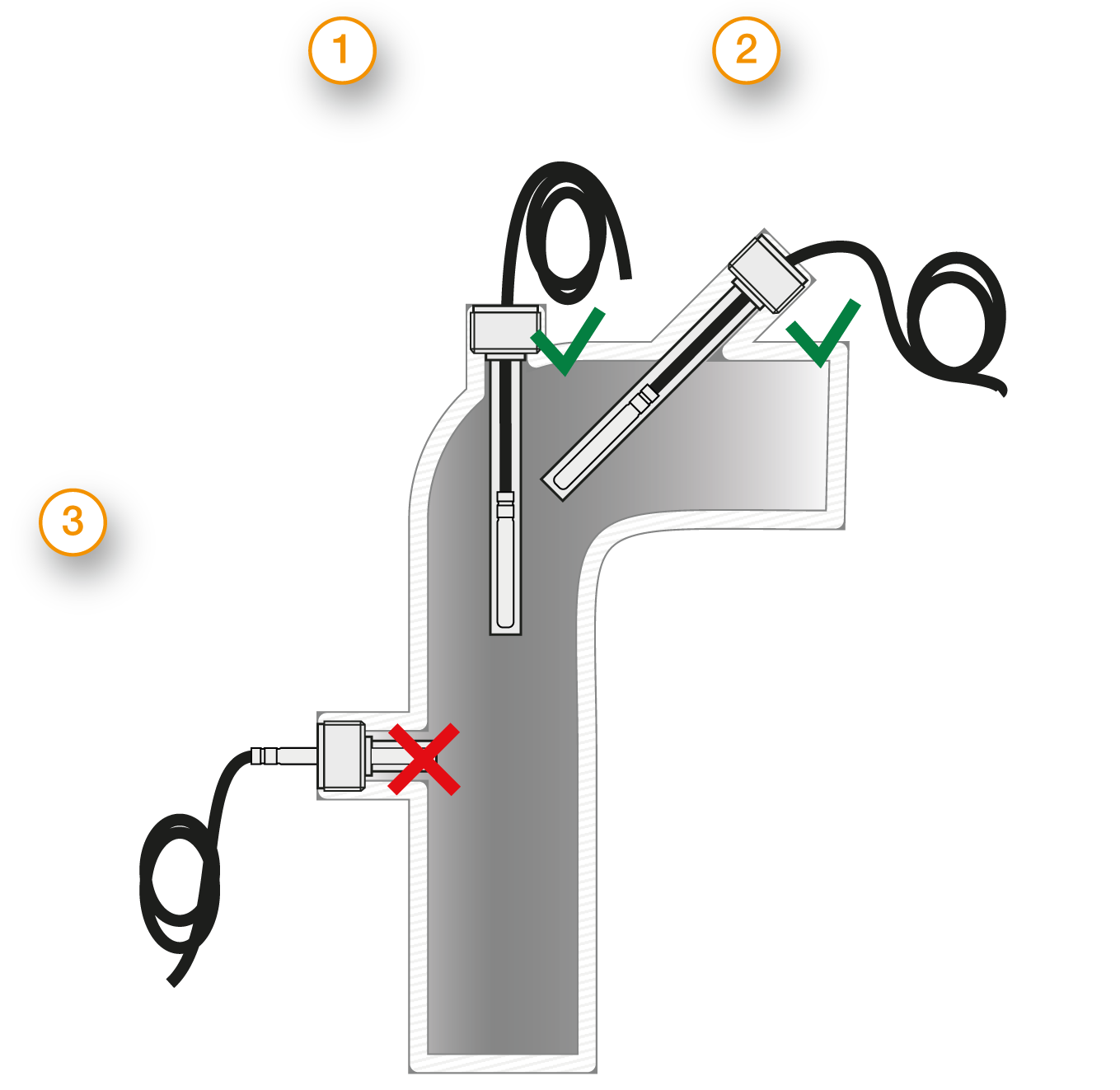

Cable probe - Important assembly advices | |||||||||||||||||||

| Measurement errors can occur due to heat dissipation to the environment. To keep these as small as possible, we recommend immersing the protection sleeve of your temperature probe as deeply as possible in the medium to be measured during installation. The optimum installation depth should be 10-15 times the Ø of the protection sleeve or, when using an immersion sleeve, the Ø of the immersion sleeve. When installing in pipelines whose Ø does not have a sufficiently deep installation depth, you should install the probe either at an angle or in a pipe elbow. Make sure that there is sufficient space for the probe to be removed. 1) Installation with sufficient installation depth 2) Installation at an angle with small pipe Ø 3) Not like this: Minimum installation depth not reached | ||||||||||||||||||

| Installation by means of compression fitting: Please tighten the union nut of the compression fitting by hand as far as it will go (clearly noticeable). For compression fittings with PTFE pressure ring, please make a 1/4 turn with a wrench suitable for the width across flats. These compression fittings can be used several times in this way. In the case of compression fittings with stainless steel cutting ring, the compression fitting connects to the protection tube. This connection is pressure resistant up to 40 bar. However, the compression fitting can only be used once. It must also be tightened more firmly. Please tighten it with 1 3/4 turns. | |||||||||||||||||||

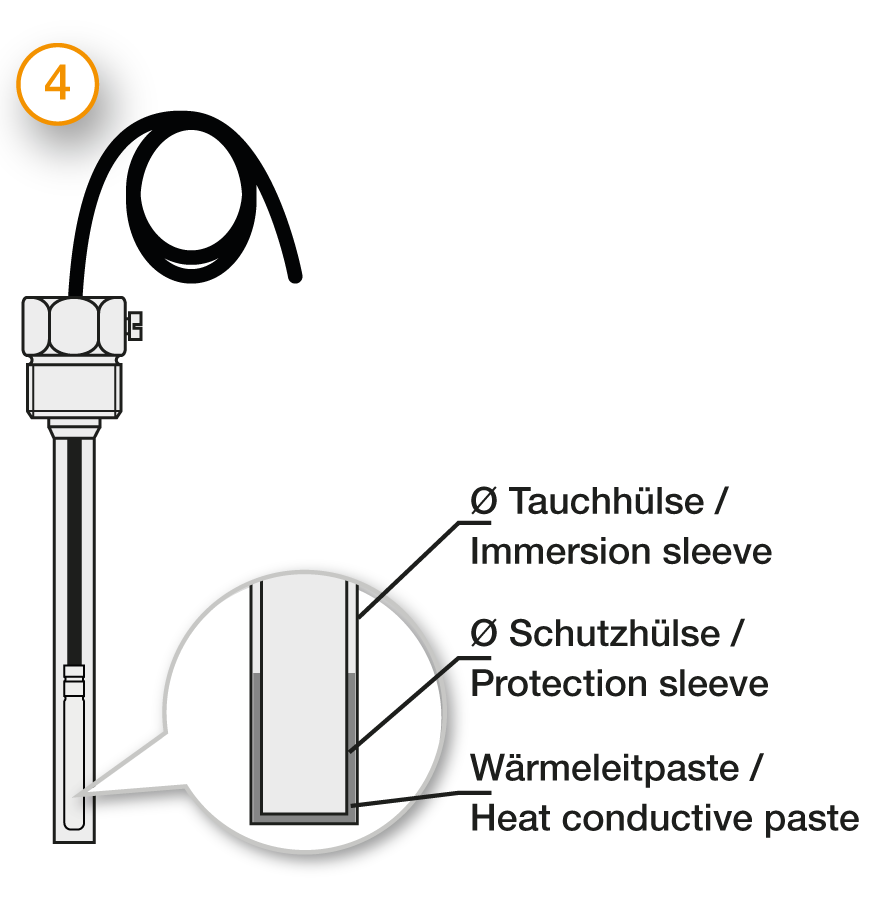

| Mounting by using an immersion sleeve (4): Please note that the Ø and the length of the immersion sleeve must be selected to suit the installation situation so that the minimum immersion depth can be achieved. Since the probe is not inserted directly into the medium, but via the immersion sleeve, the response times are somewhat slower. The probe should be selected in such a way that the protection sleeve touches the bottom of the immersion sleeve and that the air cushion around the protection sleeve is as small as possible. The use of thermal paste can improve the response times. | ||||||||||||||||||

| Please lay the cable with reserve loop (4) and in such a way that no water can penetrate the sensor head. This allows you to extend the probe without disconnecting the electrical connection. | |||||||||||||||||||

| Measuring element: | NTC 5 kOhm, Pt100 1/3 Class B, Pt100 1/10 Class B, Pt100 Class A, Pt100 Class B, Pt500 Class B, Pt1000 Class A, Pt1000 Class B |

| Temperature range: | -30 °C to +105 °C |

| Connection type: | 2-Wire, 3-Wire, 4-Wire |

| Material cable: | PVC |

| industry: | Air conditioning and ventilation technology, Automotive, Building automation, Food industry, Heating technology, Machinery and apparatus engineering, Pharmaceutical industry, Plastics industry, Refrigeration, White goods |

- Download Betriebsanleitung Temperaturfühler

- Download Operating instructions Temperature probe

- Download Datenblatt Kabelfühler verjüngt mit PVC-Leitung

- Download Bedienungsansleitung Kabelfühler verjüngt mit PVC-Leitung

- Download Instruction Manual Cable probe tapered with PVC cable

- Download Konformitätserklärung Kabelfühler verjüngt mit PVC-Leitung

- Download Kennlinie Pt100

- Download Kennlinie Pt500

- Download Kennlinie Pt1000

- Download Characteristic Pt100

- Download Characteristic Pt500

- Download Characteristic Pt1000

- Download Data Sheet Cable probe tapered with PVC cable