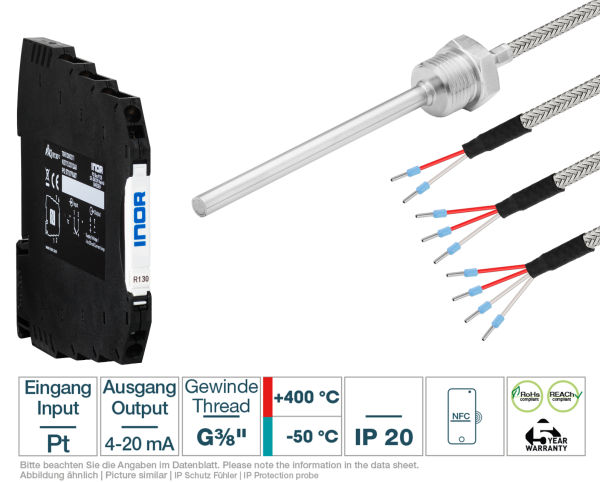

Hat rail transmitter + Screw-in probe G3/8 " glass fibre

Prices plus VAT plus shipping costs of 4,95 € to GER (incl. VAT)

Delivery time 5 Workdays to NL, BE, AT (GER -1 workdays)

Bitte prüfen Sie, welches Messelement (Thermistortyp oder Pt) für Ihre Anwendung der Passende ist. Wichtige Informationen zum Messelement entnehmen Sie bitte den Kennlinien und Datenblättern. Diese finden Sie in der Langbeschreibung oder in unserem Download-Bereich.

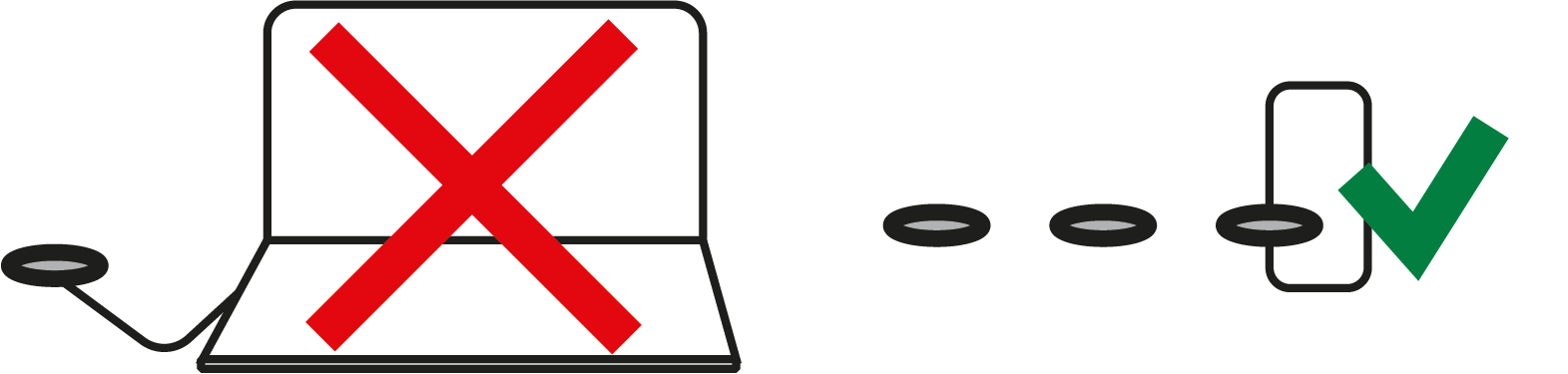

Bei Zwei-Leiter-Schaltungen addiert sich der Eigenwiderstand der Anschlussleitung zum Widerstandswert des Messwiderstands (Thermistor oder Pt) und verfälscht somit das Messergebnis. Ist der Widerstandswert des Messwiderstands groß gegenüber dem Eigenwiderstand der Anschlussleitung, so kann dieser Eigenwiderstand vernachlässigt werden. Bei Messwiderständen mit geringerem Widerstandswert (z.B. PT100), kann der Leitungseigenwiderstand die Messgenauigkeit jedoch signifikant verringern. Aus diesem Grund empfehlen wir die Zwei-Leiter-Technik in Verbindung mit kleinohmigen Messwiderständen nur dann, wenn Sie vergleichsweise kurze Anschlussleitungen, also kleinohmige Anschlussleitungen, verwenden können.

Für Applikationen, die eine sehr genaue Temperaturmessung erfordern, empfehlen wir Ihnen eine Drei- oder sogar Vier-Leiterschaltung zu verwenden.

Bei der Dreileiter-Schaltung wird der Leitungswiderstand jeder der drei angeschlossenen Leitungen mit Hilfe der dritten angeschlossenen Leitung ermittelt (alle Anschlussdrähte müssen exakt gleich lang sein) und anschließend vom gemessenen Gesamtwiderstand (Messwiderstand+Leitungswiderstand) abgezogen werden, so dass effektiv nur der Widerstandswert des Messwiderstands für die Temperaturbestimmung verwendet wird. Diese Subtraktion kann beispielsweise in der Messelelektronik automatisch durchgeführt werden.

Die sicherste und genaueste Messung erreichen Sie mit Hilfe einer Vierleiter-Schaltung. Hier wird auf jeder Seite des Messwiderstands eine zusätzliche Leitung angeschlossen. Zwei Leitungen dienen der Spannungsversorgung, die zwei anderen werden verwendet, um den Leitungswiderstand (ggf. auch asymmetrisch, also auch bei unterschiedlich langen Anschlussdrähtchen) zu ermitteln und vom Messwiderstandswert abzuziehen. Diese Subtraktion kann beispielsweise in der Messelelektronik automatisch durchgeführt werden.

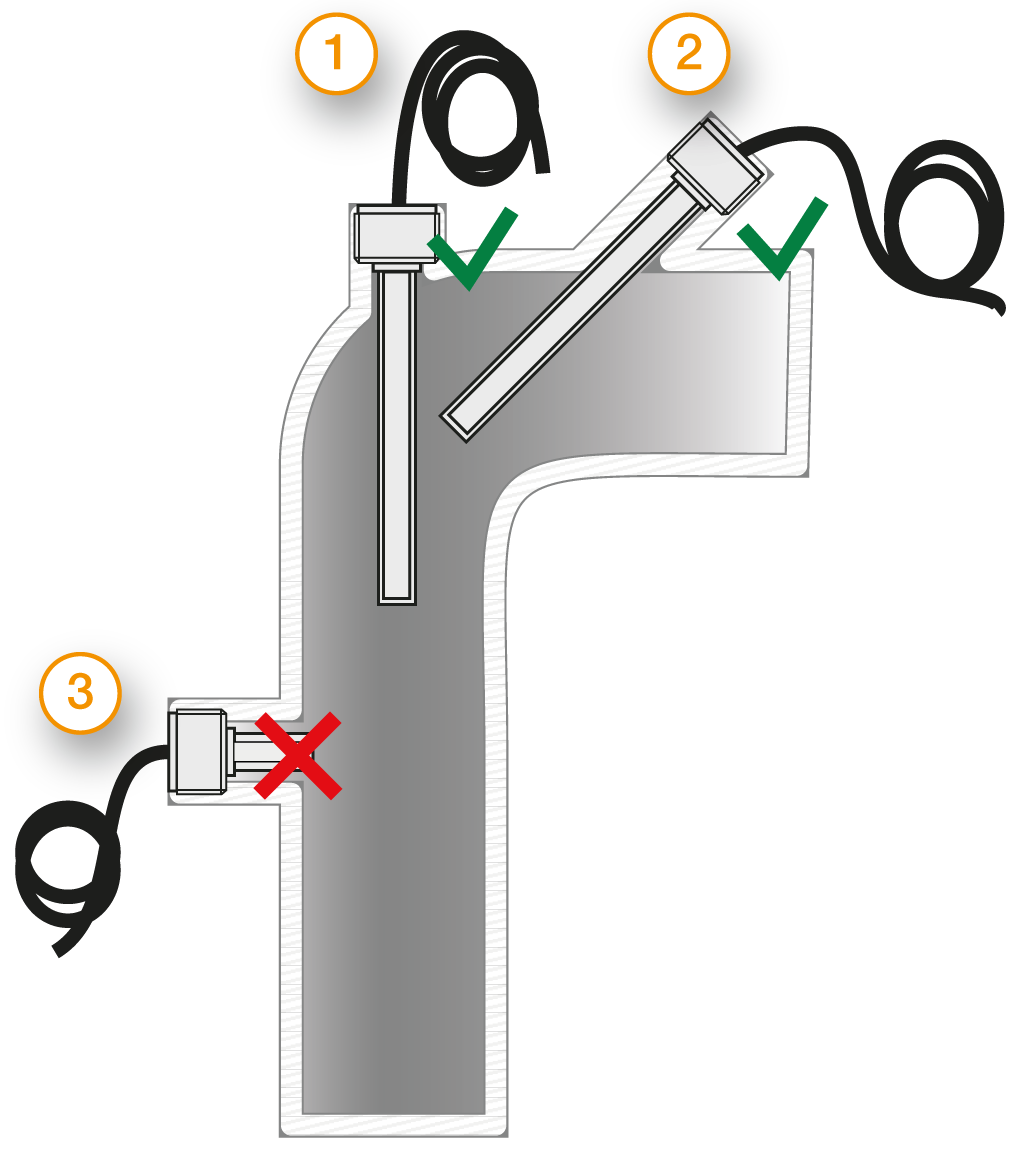

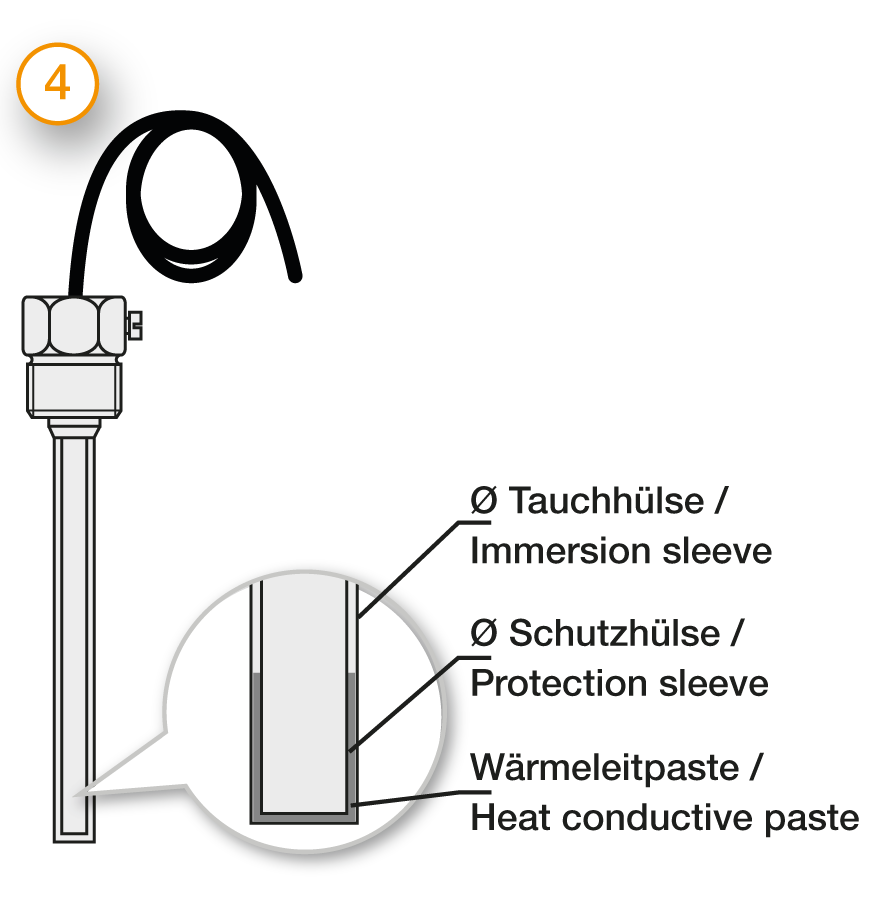

Jeder Fühler benötigt eine Mindest-Eintauchtiefe, um die Temperatur des zu messenden Mediums annehmen und korrekt messen zu können. Faustformel: optimalerweise sollte die Eintauchtiefe 10-mal dem Schutzhülsendurchmesser entsprechen, mindest sollte jedoch ein 5-facher Wert verwendet werden.

Bitte stellen Sie sicher, dass die technischen Daten der Anschlussleitung, insbesondere hinsichtlich Temperatur und IP-Schutzklasse, zu Ihrer Applikation passen. Detailierte Informationen finden Sie in unseren Datenblättern.

Temperaturbereiche unserer Leitungen:

Glasseide: -50 °C bis +400 °C

Bei sehr langen Anschlussleitungen beachten Sie bitte den Einfluss des Eigenwiderstandswerts der Leitung auf die Messgenauigkeit. Für Fühler mit Pt-oder Ni-Messelementen empfehlen wir in diesem Fall den Einsatz einer Drei- oder Vierleiterschaltung.

Der Knickschutz schützt die Anschlussleitung des Fühlers am Übergang zur Fühlerhülse vor mechanischen Belastungen (wie sie z.B. bei kleinen Biegeradien auftreten).

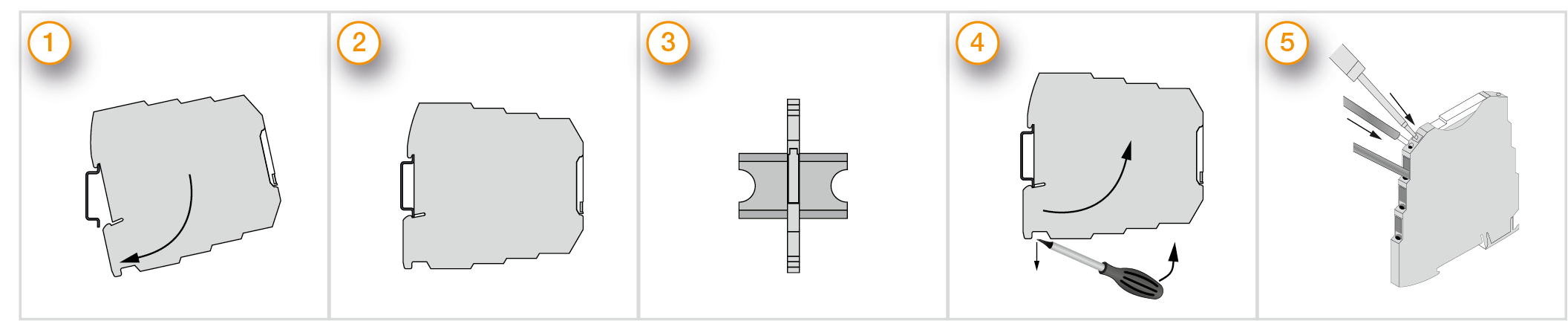

| Ihr passender Hutschienen-Transmitter: | ||

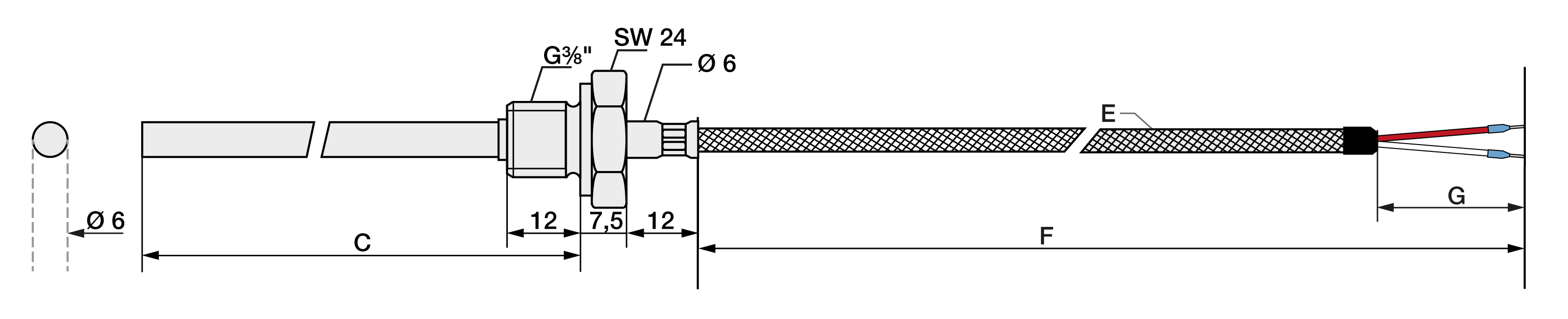

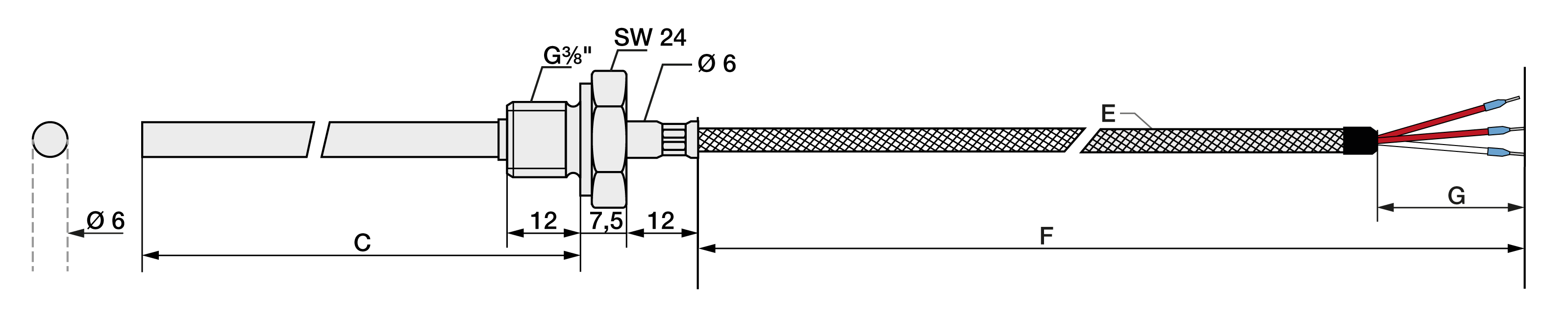

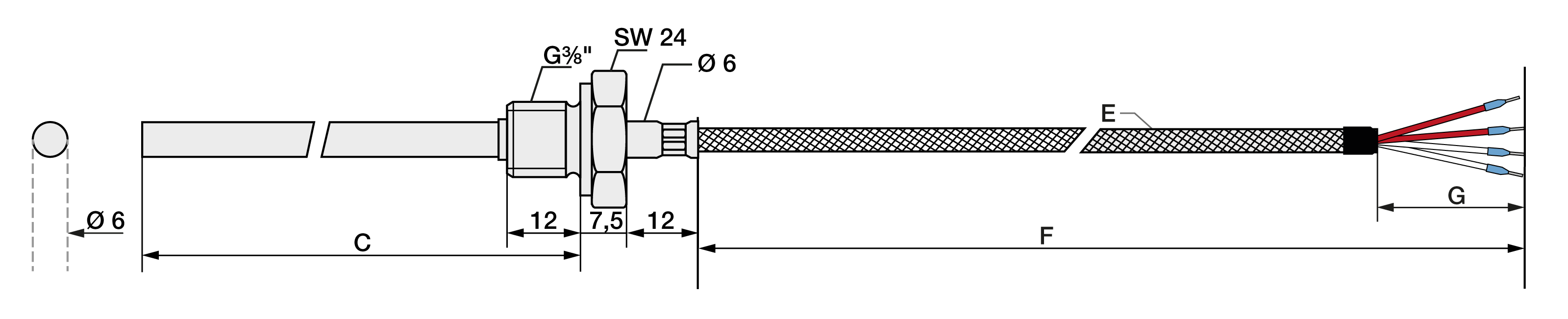

| A - Messelement: | ||

| B - Anschlussart: | ||

| C - Einbaulänge: | ||

| E - Material Anschlussleitung: | ||

| F - Länge Leitung: | ||

| G - Stecker: | ||

| H - Knickschutz: | ||

| Menge: |

- Order number: 803180-3091

Advantages

- We are ready to deliver: All information here

- Advice directly from experts

- Quality directly from the manufacturer

- Long-term stable temperature probes over years

- B2B customers welcome: All information here

Our employee will be happy to help you:

Julian Mäntele

Tel.: +49 (0)7653 96 59 771

E-Mail: jmaentele@testo-sensor.de