Prices plus VAT plus shipping costs of 4,95 € to GER (incl. VAT)

Delivery time 5 Workdays to NL, BE, AT (GER -1 workdays)

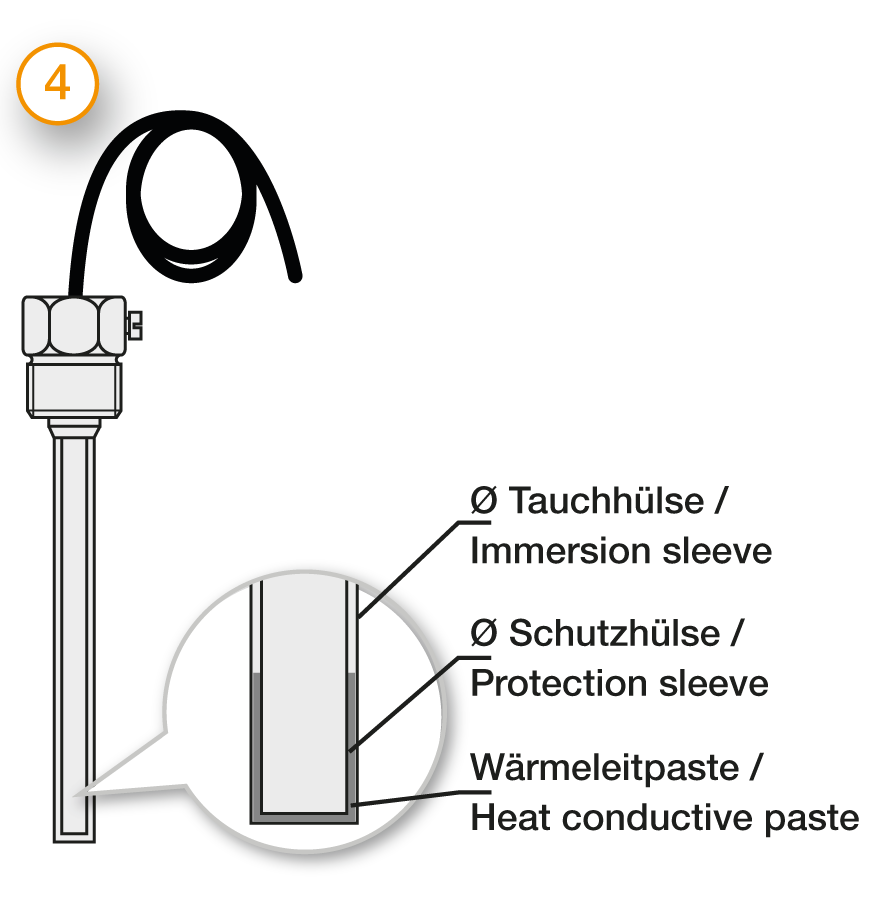

Jeder Fühler benötigt eine Mindest-Eintauchtiefe, um die Temperatur des zu messenden Mediums annehmen und korrekt messen zu können. Faustformel: optimalerweise sollte die Eintauchtiefe 10-mal dem Schutzhülsendurchmesser entsprechen, mindest sollte jedoch ein 5-facher Wert verwendet werden.

Bitte stellen Sie sicher, dass die technischen Daten der Anschlussleitung, insbesondere hinsichtlich Temperatur und IP-Schutzklasse, zu Ihrer Applikation passen. Detailierte Informationen finden Sie in unseren Datenblättern.

Temperaturbereiche unserer Leitungen:

Silikon: -50 °C bis +180 °C

Bitte beachten Sie den spezifizierten Temperaturbereich des Stecker / der Aderendenhülsen

isolierte Aderendhülsen: bis 80 °C

Mini-TE-Stecker: bis 220 °C

TE-Stecker: bis 220 °C

Der Knickschutz schützt die Anschlussleitung des Fühlers am Übergang zur Fühlerhülse vor mechanischen Belastungen (wie sie z.B. bei kleinen Biegeradien auftreten).

| Ihr passender Hutschienen-Transmitter: | ||

| C - Einbaulänge: | ||

| E - Material Anschlussleitung: | ||

| F - Länge Leitung: | ||

| G - Stecker: | ||

| H - Knickschutz: | ||

| Menge: |

- Order number: 803160-3191

Advantages

- We are ready to deliver: All information here

- Advice directly from experts

- Quality directly from the manufacturer

- Long-term stable temperature probes over years

- B2B customers welcome: All information here

Our employee will be happy to help you:

Julian Mäntele

Tel.: +49 (0)7653 96 59 771

E-Mail: jmaentele@testo-sensor.de

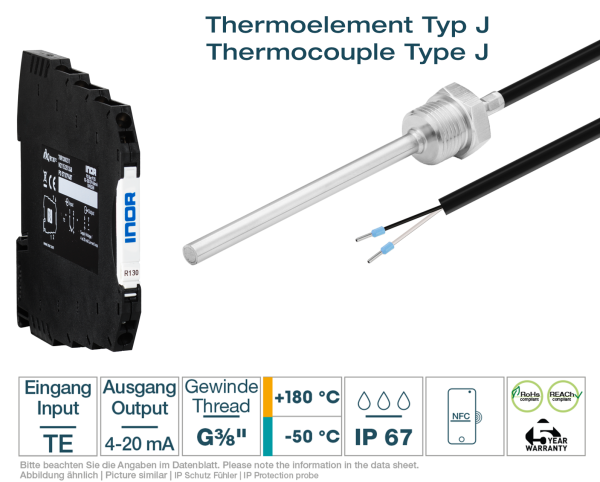

Active cable thermocouples are equipped with a temperature transmitter in DIN rail form. They convert the thermoelectric voltage into a standardized signal (mA). This means that the temperature measurement signals can always be transmitted safely, easily and even over longer distances to your control or display. Screw-in thermocouples with silicone cable measure the temperature in pipes or vessels and can be used from -50 °C to +180 °C. Silicone seals well and remains flexible even at temperatures below freezing.

________________________________

The APAQ R130 TC for thermocouples is a DIN rail transmitter for installation on standard DIN rails according to DIN EN50022. The sophisticated product design leaves sufficient space for mounting. It is optimally designed for use in plant and machine construction and is characterized by high accuracy, reliability, long-term stability and its robust product design. The transmitter is extremely insensitive to external influences such as vibration and EMC interference. Installation and commissioning are particularly user-friendly. For example, parameterization can be carried out wirelessly, conveniently and easily via the cell phone app using NFC technology. The monitoring functions such as sensor break monitoring, sensor short-circuit and measuring range monitoring can also be activated via this.

Here you can find our downloads for Hat rail transmitter for thermocouples APAQ-R130

Hat rail transmitter - Special features | ||||||||||||||||

| Inputs and outputs | Input: thermocouples Output: 4 to 20mA, temperature linear output signal | |||||||||||||||

| Accuracy & Long-term stability | Accuracy: depending on thermocouple Long-term stability: max drift of ±0.05°C or ±0.05% of span |year | |||||||||||||||

| Design | Robust - vibration and shock resistant design Suitable for hat rails according to DIN EN50022 Compact housing design Facilitated mounting | |||||||||||||||

| Parametrization | Configuration - wireless via NFC technology Free app for Iphone, Android & Huawei Parameterization templates for fast mass configuration Simple configuration with "copy and paste" in no time at all  | |||||||||||||||

| Alarm function | configurable via app Sensor break monitoring Sensor short circuit Measuring range monitoring | |||||||||||||||

Hat rail transmitter - Input Thermocouple | ||||||||||||||||

| Measuring element | Material / Raw Material | Norm | Maximum configurable measuring range | Min. Span | Accuracy | |||||||||||

| Type B | Pt30Rh-Pt6Rh | IEC 60584 | 0 °C to +1820 °C 32 °F to +3308 °F | +700 °C | +1292 °F | +100 °C to +400 °C: ±10 °C >400 °C: ±2 °C / 0,2% 1} | |||||||||||

| Type E | NiCr-CuNi | IEC 60584 | -270 °C to +1000 °C -454 °F to +1832 °F | +50 °C | +122 °F | ±1 °C| ±0,2 % 1} | |||||||||||

| Type J | Fe-CuNi | IEC 60584 | -210 °C to +1200 °C -346 °F to +2192 °F | +50 °C | +122 °F | ±1 °C| ±0,2 % 1} | |||||||||||

| Type K | NiCr-Ni | IEC 60584 | -270 °C to +1300 °C -454 °F to +2372 °F | +50 °C | +122 °F | ±1 °C| ±0,2 % 1} | |||||||||||

| Type N | NiCrSi-NiSi | IEC 60584 | -100 °C to +1300 °C -148 °F to +2372 °F | +100 °C | +212 °F | ±1 °C| ±0,2 % 1} | |||||||||||

| Type N | NiCrSi-NiSi | IEC 60584 | -270 °C to -100 °C -418 °F to +148 °F | +100 °C | +212 °F | ±2 °C 1} | |||||||||||

| Type R | Pt13Rh-Pt | IEC 60584 | -50 °C to +1750 °C -58 °F to +3182 °F | +300 °C | +572 °F | ±2 °C| ±0,2 % 1} | |||||||||||

| Type S | Pt10Rh-Pt | IEC 60584 | -50 °C to +1750 °C -58 °F to +3182 °F | +300 °C | +572 °F | ±2 °C| ±0,2 % 1} | |||||||||||

| Type T | Cu-CuNi | IEC 60584 | -270 °C to +400 °C -454 °F to +752 °F | +50 °C | +122 °F | ±2 °C| ±0,2 % 1} | |||||||||||

| 1} of span (cold junction compensation error is not included) | ||||||||||||||||

| Input impedance | >10 MΩ | |||||||||||||||

| Max. wire loop resistance | 5 kΩ | |||||||||||||||

| Cold Junction Compensation | Internal or external | |||||||||||||||

Hat rail transmitter - General information about the input | ||||||||||||||||

| Zero adjustment | Within measuring range | |||||||||||||||

Hat rail transmitter - Output | ||||||||||||||||

| Output type | analog, temperature linear for TC |  | ||||||||||||||

| Output signal (mA) | 4 to 20 | |||||||||||||||

| Parametrization / Scaling | Configurable via NFC | |||||||||||||||

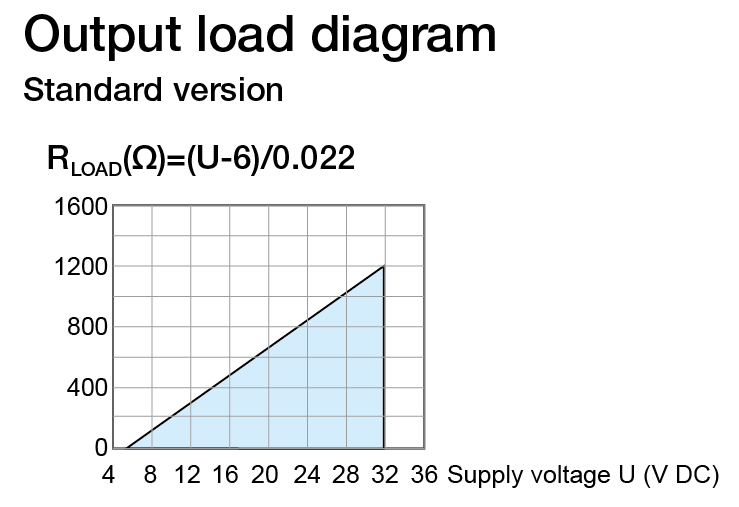

| Load | 818 Ω at 24 VDC | |||||||||||||||

| Connection type | 2-wire | |||||||||||||||

Hat rail transmitter - Time response | ||||||||||||||||

| Closing time / Update time (Inor) | ~150 - 300 | |||||||||||||||

| Heating period | After approx. 20 min. the typical accuracy is reached | |||||||||||||||

| Signal attenuation / Ajustable output filtering (Inor) | 0,4 to 26 adjustable via App | |||||||||||||||

| Measuring cycle | < 1 | |||||||||||||||

Hat rail transmitter - Sensor monitoring & sensor error | ||||||||||||||||

| Sensor break / Short circuit | Upscale (≥21.0 mA) or Downscale (≤3.6 mA) | |||||||||||||||

| Sensor failure effects (Inor) | according to NAMUR NE43 | |||||||||||||||

Hat rail transmitter - Accuracy and stability | ||||||||||||||||

| Temperature influence | ||||||||||||||||

| TC Type B, E, J, K, R, S, T | see table below | |||||||||||||||

| TC Type N (-100...+1300 °C) | ±0,01 % < 4000 Ω 2} < ±0,02 % of span per °C | |||||||||||||||

| TC Type N (-270...-100 °C) | ±0,01 % of span per °C | |||||||||||||||

| Influence of the sensor cable | ||||||||||||||||

| Thermocouples and Voltage | Negligible | |||||||||||||||

| Further data | ||||||||||||||||

| Supply voltage influence | <±0.005 % of span per volt | |||||||||||||||

| Long-term drift | ±0.05 % of span per year | |||||||||||||||

Hat rail transmitter - Type | ||||||||||||||||

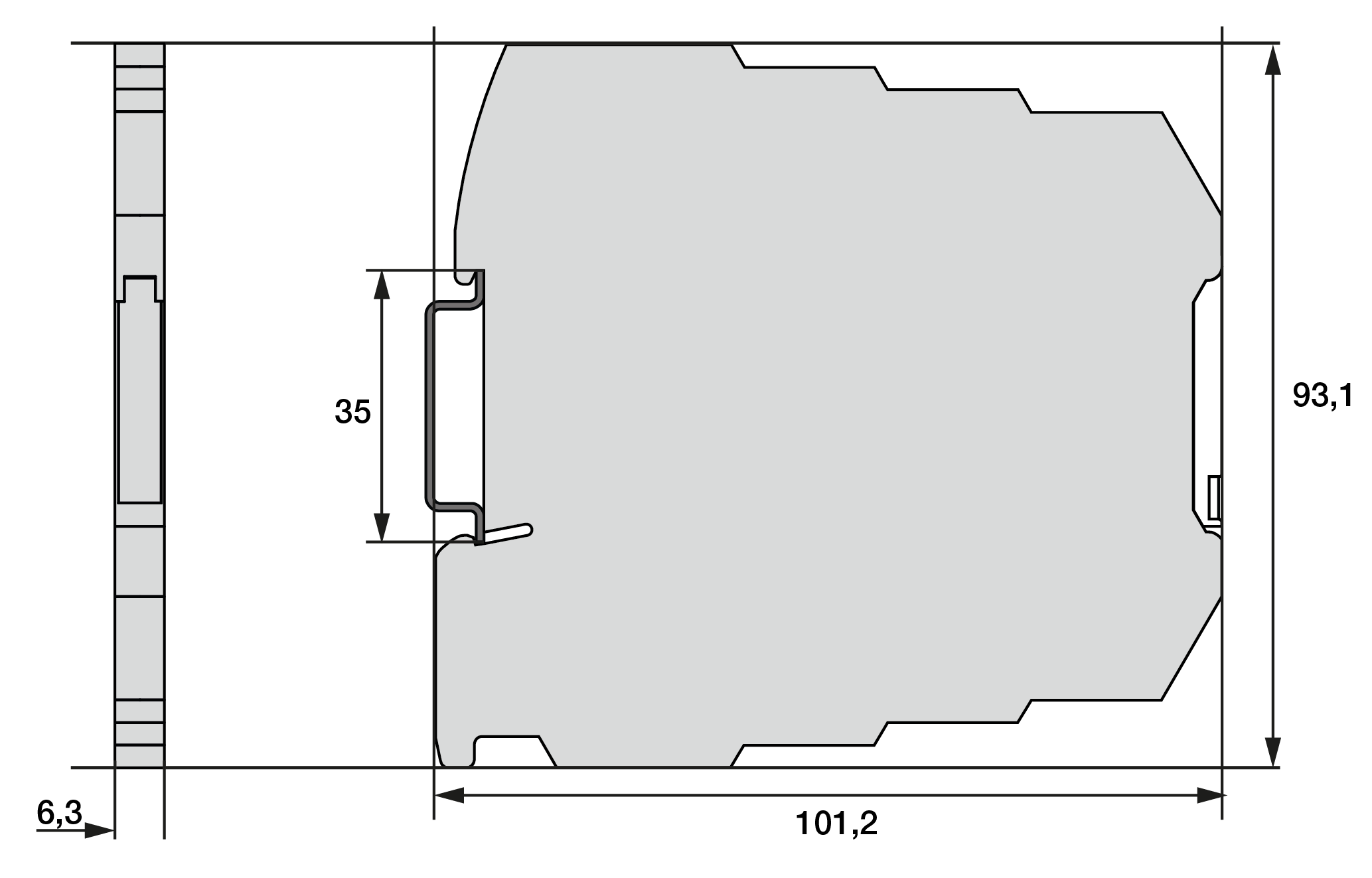

| Dimensions | See drawing |  | ||||||||||||||

| Material | Flammability | V0/HB, RoHS compliant | |||||||||||||||

| Mounting | 35 mm hat rail according to DIN 50022 / EN 60715 | |||||||||||||||

| Connection | Single wires, max. 1,5 mm², AWG 16 | |||||||||||||||

| Weight | 40 | All dimensions in mm | ||||||||||||||

Hat rail transmitter - General data | ||||||||||||||||

| Isolation | none | |||||||||||||||

| Supply Voltage (VDC) | 8 to 32, polarity protected | |||||||||||||||

Hat rail transmitter - Ambient conditions | ||||||||||||||||

| Ambient Temperatur | Storage: -40 °C to +85 °C | -40 °F to +185 °F Operating: -40 °C to +85 °C | -40 °F to +185 °F | |||||||||||||||

| Humidity | 0 to 98 (non-condensing) | |||||||||||||||

| Protection | Housing IP20 | Anschlussklemmen IP00 | |||||||||||||||

| Vibration | according to IEC 60068-2-6, Test Fc, 10bis2000 Hz, 10 g | |||||||||||||||

| Shock | according to IEC-60068-2-27, test Ea | |||||||||||||||

| Environmental influences | according to IEC 60068-2-31:2008, Test Ec | |||||||||||||||

Hat rail transmitter - EMC | ||||||||||||||||

| Standard | Directive: 2014/30/EU | Harmonized standards: EN 61326-1, EN 61326-2-3 | |||||||||||||||

| Immunity performance | ESD, radiated EMC fields, magnetic fields: Criterion A Burst, conducted RF: Criteria A Overvoltage: standard deviation 1% of span | |||||||||||||||

Hat rail transmitter - Factory configuration (if not ordered otherwise) | ||||||||||||||||

| Input | Pt100, 3-wire, 0 °C to 100 °C | |||||||||||||||

| Output (mA) | 4 to 20 | |||||||||||||||

| Sensor control | Upscale (≥21.0 mA) | |||||||||||||||

Hat rail transmitter - Mounting | ||||||||||||||||

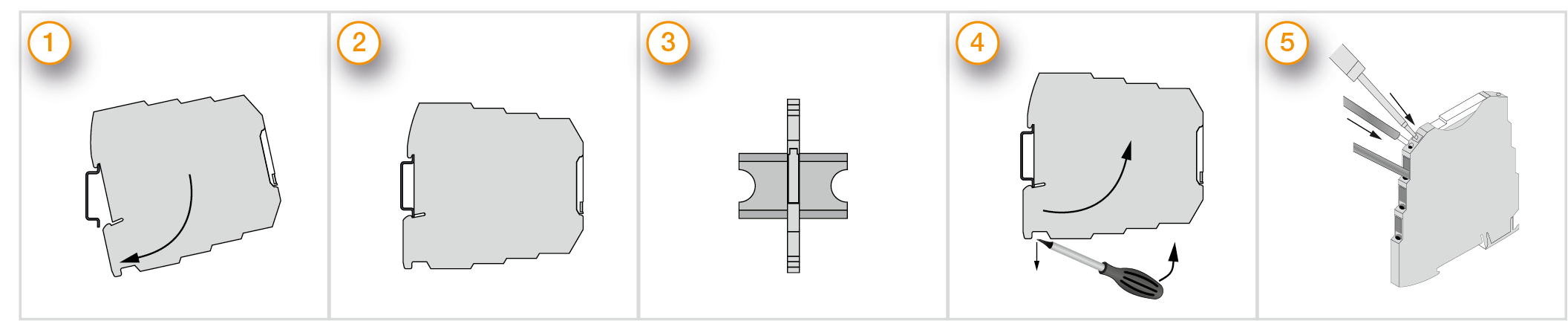

| You can easily mount the APAQ R130 hat rail transmitter on 35mm hat rails according to DIN EN50022. The mounting is easy because you can fix the transmitter on the rail without any tools. Mounting material for the installation of the transmitter is available as accessory. Important: To prevent measuring errors, the connecting screws for fastening the connecting cable must be tightened firmly. | ||||||||||||||||

| ||||||||||||||||

| Mounting and dismounting of the transmitter (1) Fix the upper part of the transmitter on the rail (2) Then press the lower part of the transmitter onto the rail. The electrical connection is made according to the wiring diagram (4) To remove the transmitter, use a screwdriver and bend the latch downwards | ||||||||||||||||

Hat rail transmitter - Configuration | Parametrization | ||||||||||||||||

Before making a configuration of APAQ C130TC you need to do following: Make sure that you have a mobile device with NFC communication activated. Download the app INOR Connect to your mobile device. Required versions: iOS: iOS 13 or later and Iphone 7 or later Android: Android 4.4 or later | Configuration procedure: Launch the app by clicking on the App icon or holding your mobile device against the transmitter on the part of the device where NFC is located (only possible with Android). Click on “Read Configuration” and hold your mobile device against the transmitter as explained in the first section. In the app you can edit the following: Sensor type and number of wire circuits Measuring range Upscale or Downscale sensor control TAG-number Password settings In the configuration window you can enter and change the parameters. The selected configuration is transferred to the transmitter by clicking the "Send to transmitter" button. After the transfer is completed, the transmitter uses the new parameters. | |||||||||||||||

________________________________

Screw-in thermocouples with silicone cable measure the temperature in pipes or vessels and can be used from -50 °C to +180 °C. Silicone seals well and remains flexible even at temperatures below freezing.

Here you can find our downloads for the Thermocouple type J G3/8 " with silicone cable

Thermocouple G3/8 " - General Information | |||||||||||||||||||

| Measuring range | -40 °C to +180 °C | ||||||||||||||||||

| Perm. °C range cable | -50 °C to +180 °C | ||||||||||||||||||

| Accuracy | -40 °C to +375 °C: ±1,5 °C according to DIN IEC 60584 Class 1 | ||||||||||||||||||

| Response time | t63 / t99: information is available on request | ||||||||||||||||||

| Pull-out force | ≥ 30 N | ||||||||||||||||||

Thermocouple G3/8 " - Supply and output | |||||||||||||||||||

| Measuring element | Thermocouple Type J | ||||||||||||||||||

| Measuring point | Measuring point isolated | ||||||||||||||||||

| Measurement signal | Thermovoltage | ||||||||||||||||||

Thermocouple G3/8 " - Ambient conditions | |||||||||||||||||||

| Protection class | IP65 according DIN 60529 (depending on cable) | ||||||||||||||||||

| Humidity and moisture condensation resistance | according to application-specific qualification | ||||||||||||||||||

Thermocouple G3/8 " - Certificates and Standards | |||||||||||||||||||

| Standards | DIN EN 61326-1:2013 | DIN EN IEC 63000:2019-05 | ||||||||||||||||||

| Directive | RoHS 2011/65/EU | 2014/30/EU | ||||||||||||||||||

| Certificates | Certificate of suitability (on request) | ||||||||||||||||||

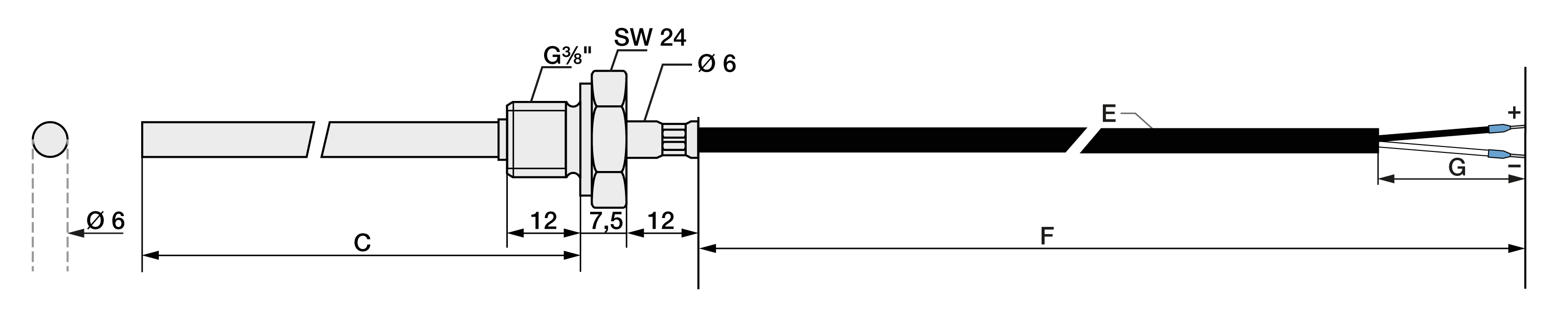

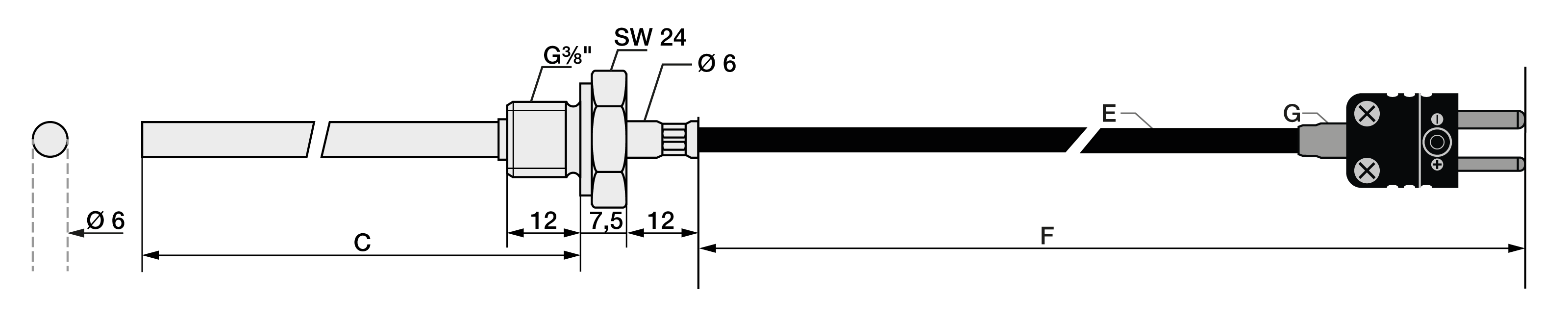

Thermocouple G3/8 " - Technical Drawing | |||||||||||||||||||

| |||||||||||||||||||

| C - Mounting length | |||||||||||||||||||

| E - Material connection cable | |||||||||||||||||||

| |||||||||||||||||||

| F - Length connection cable | |||||||||||||||||||

| H - Bend protection | |||||||||||||||||||

| |||||||||||||||||||

| G - Connector | |||||||||||||||||||

| All dimensions in mm | |||||||||||||||||||

Thermocouple G3/8 " - Screw-in thread | |||||||||||||||||||

| Thread | |||||||||||||||||||

| Material thread | Stainless steel 1.4301 | SUS 304 |  | |||||||||||||||||

| Length (mm) | 12 | ||||||||||||||||||

| Thread | G3/8 " | ||||||||||||||||||

| Wrench size | 24 | ||||||||||||||||||

| Protection sleeve | |||||||||||||||||||

| Material | Stainless steel 1.4571 | 316TI | ||||||||||||||||||

| Diameter (mm)1} | 6 | ||||||||||||||||||

| Mounting length (mm)2} | 50, 100, 150, 200, 250, 300, 400, 500 | ||||||||||||||||||

| 1} Tolerance ± 0,1 mm | 2} Tolerance ± 1% | |||||||||||||||||||

Thermocouple G3/8 " - Thermocouple cable | |||||||||||||||||||

| Type | Color | Material (Outside / Inside) | Perm. range °C | Ø Outside (mm) | Cross section (mm²) | Color strand | Ω / m | |||||||||||

| Thermocouple cable | Type J1} | FEP / Silicone | -50 to +180 | 3,6 ± 0,2 | 0,22 | bk, wt | 2,502} | ||||||||||||

| Length (m) | 1, 2, 3, 4, 5, 10, 15, 20 | ||||||||||||||||||

| Insulation resistance: ≥ 100 MOhm at min. 100 VDC | 1}Color according to IEC 584 | 2}per thermocouple | Cable available as accessory | |||||||||||||||||||

Thermocouple G3/8 " - Connector | |||||||||||||||||||

| Insulated end ferrules (50 mm) | |||||||||||||||||||

| Mini-TC connector Type J bk | |||||||||||||||||||

| TC connector Type J bk | |||||||||||||||||||

Thermocouple G3/8 " - Bend protection | |||||||||||||||||||

| Version | Without (Standard), Metal bend protection | ||||||||||||||||||

| Length (mm) | 50 | ||||||||||||||||||

| Material | Stainless steel spring 1.4310 | SUS 302 | ||||||||||||||||||

Thermocouple G3/8 " - Delivery | |||||||||||||||||||

| Assembly instructions | per process connection | ||||||||||||||||||

| Delivery and Packaging | Probe, seperatly packaged in PE bag | ||||||||||||||||||

| Matching accessories | Heat-conducting paste | ||||||||||||||||||

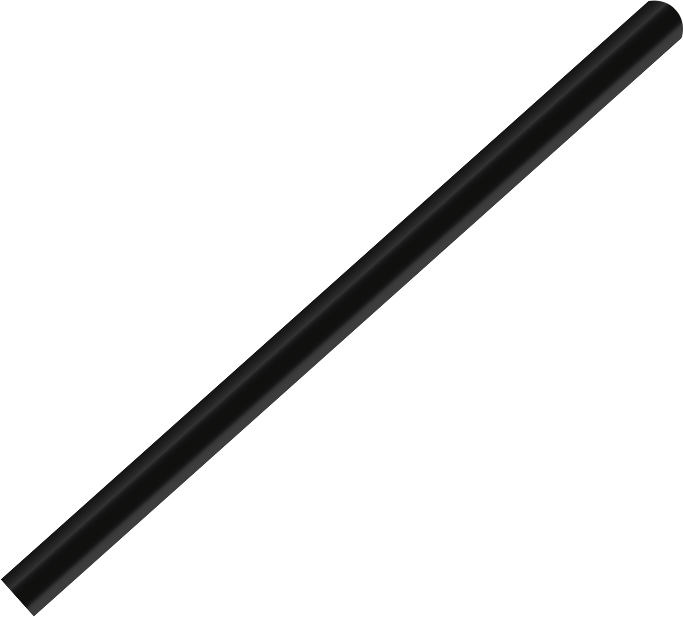

Thermocouple G3/8 " - Important assembly advices | |||||||||||||||||||

| Measurement errors can occur due to heat dissipation to the environment. To keep these as small as possible, we recommend immersing the protection sleeve of your temperature probe as deeply as possible in the medium to be measured during installation. The optimum installation depth should be 10-15 times the Ø of the protection sleeve or, when using an immersion sleeve, the Ø of the immersion sleeve. When installing in pipelines whose Ø does not have a sufficiently deep installation depth, you should install the probe either at an angle or in a pipe elbow. Make sure that there is sufficient space for the probe to be removed. 1) Installation with sufficient installation depth 2) Installation at an angle with small pipe Ø 3) Not like this: Minimum installation depth not reached | ||||||||||||||||||

| Installation by using an immersion sleeve (4): Please ensure that the Ø and length of the immersion sleeve are selected to suit the installation situation so that the minimum immersion depth can be achieved. Please also pay attention to the correct process connection. Since the probe is not inserted directly into the medium, but via the immersion sleeve, the response times are somewhat slower. The probe should be selected in such a way that the protection sleeve touches the bottom of the immersion sleeve and that the air cushion around the protection sleeve is as small as possible. The use of thermal paste can improve the response times. | ||||||||||||||||||

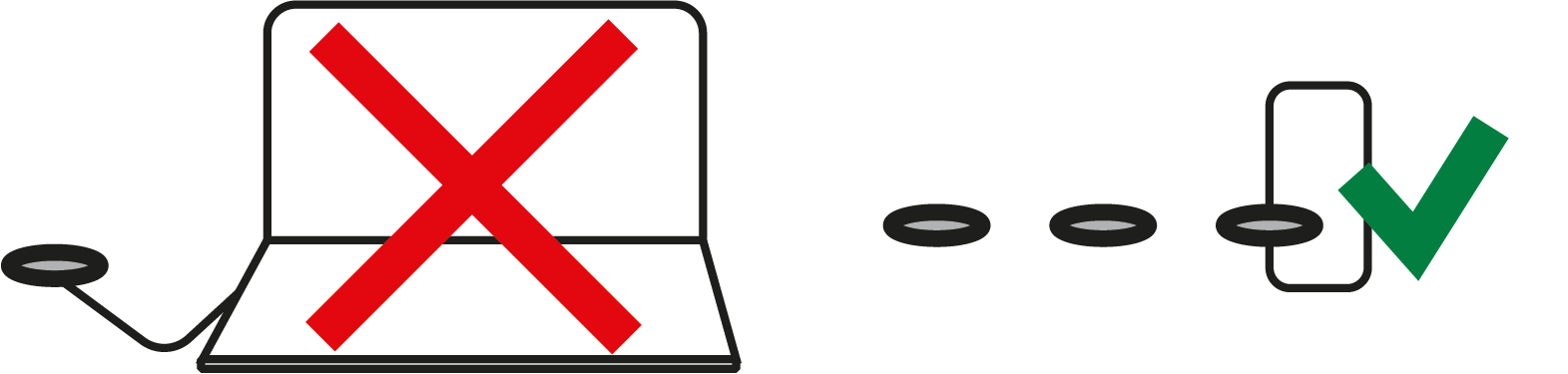

| Please lay the cable in such a way that no water can penetrate the probe and with reserve loop (4). This allows you to extend the probe without disconnecting the electrical connection. | |||||||||||||||||||

Qualification measurement series to ensure the function of our temperature probes over their service life | |||||||||||||||||||

| Robust even with temperature changes | Temperature probes are exposed to harsh environmental conditions, such as changing temperatures and humidity, and should still work reliably in the field for 15 years or more. | |||||||||||||||||

| Resistant to heat and humidity | Extremely varying ambient conditions cause immense stress for the temperature probe and the design must be suitably robust and qualified. | |||||||||||||||||

| Long-term stable in any weather | Continuous exposure to sunlight, snow, fog, cold and ice shall not impair the function of the temperature probe and compliance with the specification. | |||||||||||||||||

| Robust even under high vibration load | Depending on the application, compressors and fans generate strong vibrations which are transmitted to components and cables. Therefore the used temperature probes have to be vibration resistant (20g). | |||||||||||||||||

| Reliable in practice: high pull-out force | The robust design ensures the necessary cable pull-out resistance, even under vibration and higher temperatures. | |||||||||||||||||

| Efficient through short response time | Depending on the application, short response times may be necessary to ensure efficient control of the system. Our sensor design is optimised for this requirement and we prove response times. | |||||||||||||||||

| Corrosion-resistant even in salt spray | Temperature probes are also used in coastal regions. For this reason, the temperature probes must also be able to withstand salty air for a lifespan of 15 years. | |||||||||||||||||

Applicable for this probe type | |||||||||||||||||||

| industry: | Automotive, Cement and building materials industry, Glass industry, Heating technology, Machinery and apparatus engineering, Plastics industry, Power generation, Steel and iron industry, Waste recycling/incineration |

| Material cable: | Silicone |

| Process connection: | G3/8 " |

| Temperature range: | -40 °C to +180 °C |

| Thermocouple: | Type J Class 1 |

| Output: | 4-20 mA |

| Input: | Thermocouple |

| Type: | Hat rail transmitter |

- Download Datenblatt Hutschienen-Transmitter für Thermoelemente APAQ-R130

- Download Bedienungsansleitung Hutschienen-Transmitter für Thermoelemente APAQ-R130

- Download Konformitätserklärung Hutschienen-Transmitter für Thermoelemente APAQ-R130

- Download Datenblatt Thermoelement Typ J G1/2 " mit PFA-Leitung

- Download Data Sheet Thermocouple type J G1/2 " with PFA cable

- Download Bedienungsansleitung Thermoelement Typ J G1/2 " mit PFA-Leitung

- Download Konformitätserklärung Thermoelement Typ J G1/2 " mit PFA-Leitung

- Download Kennlinie Thermoelement Typ J

- Download Characteristic thermocouple type J

- Download Betriebsanleitung Thermoelemente

- Download Operating instructions Thermocouple