Prices plus VAT plus shipping costs of 4,95 € to GER (incl. VAT)

Delivery time 5 Workdays to NL, BE, AT (GER -1 workdays)

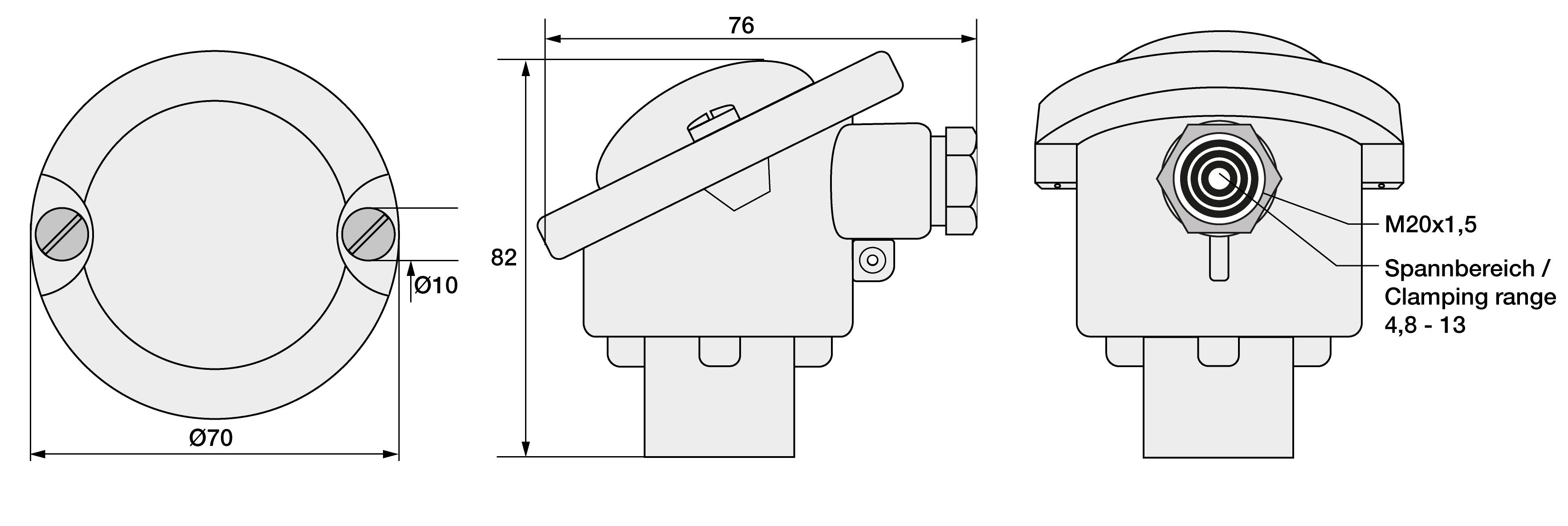

Jeder Fühler benötigt eine Mindest-Eintauchtiefe, um die Temperatur des zu messenden Mediums annehmen und korrekt messen zu können. Faustformel: optimalerweise sollte die Eintauchtiefe 10-mal dem Schutzhülsendurchmesser entsprechen, mindest sollte jedoch ein 5-facher Wert verwendet werden.

| C - Einbaulänge: | ||

| Menge: |

- Order number: 805311-1111

Advantages

- We are ready to deliver: All information here

- Advice directly from experts

- Quality directly from the manufacturer

- Long-term stable temperature probes over years

- B2B customers welcome: All information here

Our employee will be happy to help you:

Julian Mäntele

Tel.: +49 (0)7653 96 59 771

E-Mail: jmaentele@testo-sensor.de

Our duplex immersion probe thermoelment type J with B-head can be used in a temperature range up to +750 °C. It has two thermocouples built in. This allows you, for example, to operate two different evaluation units or to increase reliability in safety-relevant processes. In complicated installation situations, you can simply switch to the second thermocouple instead of removing the probe. The probes are installed in direct contact with the medium or using immersion sleeves. We offer brass or stainless steel immersion sleeves as well as mounting flanges and compression fittings made of different materials as accessories.

Here you can find our downloads for the Double thermocouple type J with B-Head

Immersion double thermocouple with head - General Information | |||||||||||||||||||

| Measuring range | -40 °C to +750 °C | ||||||||||||||||||

| Perm. (°C) conn. head | -40 °C to +100 °C | ||||||||||||||||||

| Accuracy | -40 °C to +375 °C: ±1,5 °C | 375 °C to 750 °C: ±0,004 |t| according to DIN IEC 60584 Class 1 | ||||||||||||||||||

| Response time | t63 / t99: information is available on request | ||||||||||||||||||

Immersion double thermocouple with head - Supply and output | |||||||||||||||||||

| Measuring element | 2 x Thermocouple Type J | ||||||||||||||||||

| Measuring point | Measuring point isolated | ||||||||||||||||||

| Measurement signal | Thermovoltage | ||||||||||||||||||

Immersion double thermocouple with head - Ambient conditions | |||||||||||||||||||

| Protection class | IP65 according DIN 60529 | ||||||||||||||||||

| Humidity and moisture condensation resistance | according to application-specific qualification | ||||||||||||||||||

Immersion double thermocouple with head - Certificates and Standards | |||||||||||||||||||

| Standards | DIN EN 61326-1:2013 | DIN EN IEC 63000:2019-05 | ||||||||||||||||||

| Directive | RoHS 2011/65/EU | 2014/30/EU | ||||||||||||||||||

| Certificates | Certificate of suitability (on request) | ||||||||||||||||||

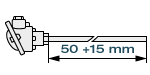

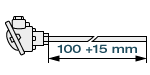

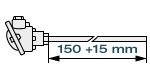

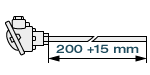

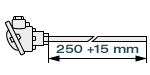

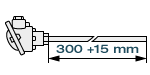

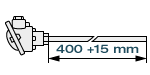

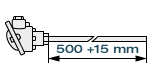

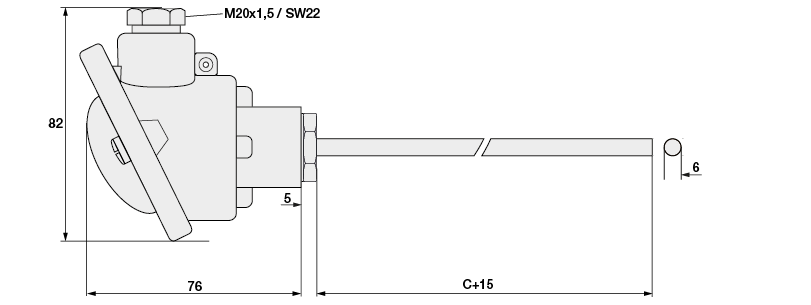

Immersion double thermocouple with head - Technical Drawing | |||||||||||||||||||

| |||||||||||||||||||

| C - Mounting length | |||||||||||||||||||

| All dimensions in mm | |||||||||||||||||||

Immersion double thermocouple with head - Protection sleeve | |||||||||||||||||||

| Material | Stainless steel 1.4571 | 316TI | ||||||||||||||||||

| Diameter (mm)1} | 6 | ||||||||||||||||||

| Mounting length (mm)2} | 50, 100, 150, 200, 250, 300, 400, 500 | ||||||||||||||||||

| 1} Tolerance ± 0,1 mm | 2} Tolerance ± 1% | Please note: For this type the mounting length is 15 mm longer | |||||||||||||||||||

Immersion double thermocouple with head - Connection head | |||||||||||||||||||

| Design | Form B | ||||||||||||||||||

| Material | Aluminium | ||||||||||||||||||

| W/H/Ø (mm) | 76/82/70 | ||||||||||||||||||

| Color | RAL 9006 aluminium silver | ||||||||||||||||||

| Cable gland | with strain relief | ||||||||||||||||||

| Cable electricial connection | Screw terminals max. 2,5mm² | ||||||||||||||||||

| Clamping range (mm) | 4,8 to 13 | ||||||||||||||||||

| Sensor unit | Fixed | ||||||||||||||||||

| |||||||||||||||||||

Immersion double thermocouple with head - Delivery | |||||||||||||||||||

| Assembly instructions | by means of existing protection sleeve, mounting flange, thermowell or compression fitting. | ||||||||||||||||||

| Delivery and Packaging | Probe, seperatly packaged in PE bag | ||||||||||||||||||

| Matching accessories | Immersion sleeve, Heat-conducting paste, Compression fitting, Mounting flange | ||||||||||||||||||

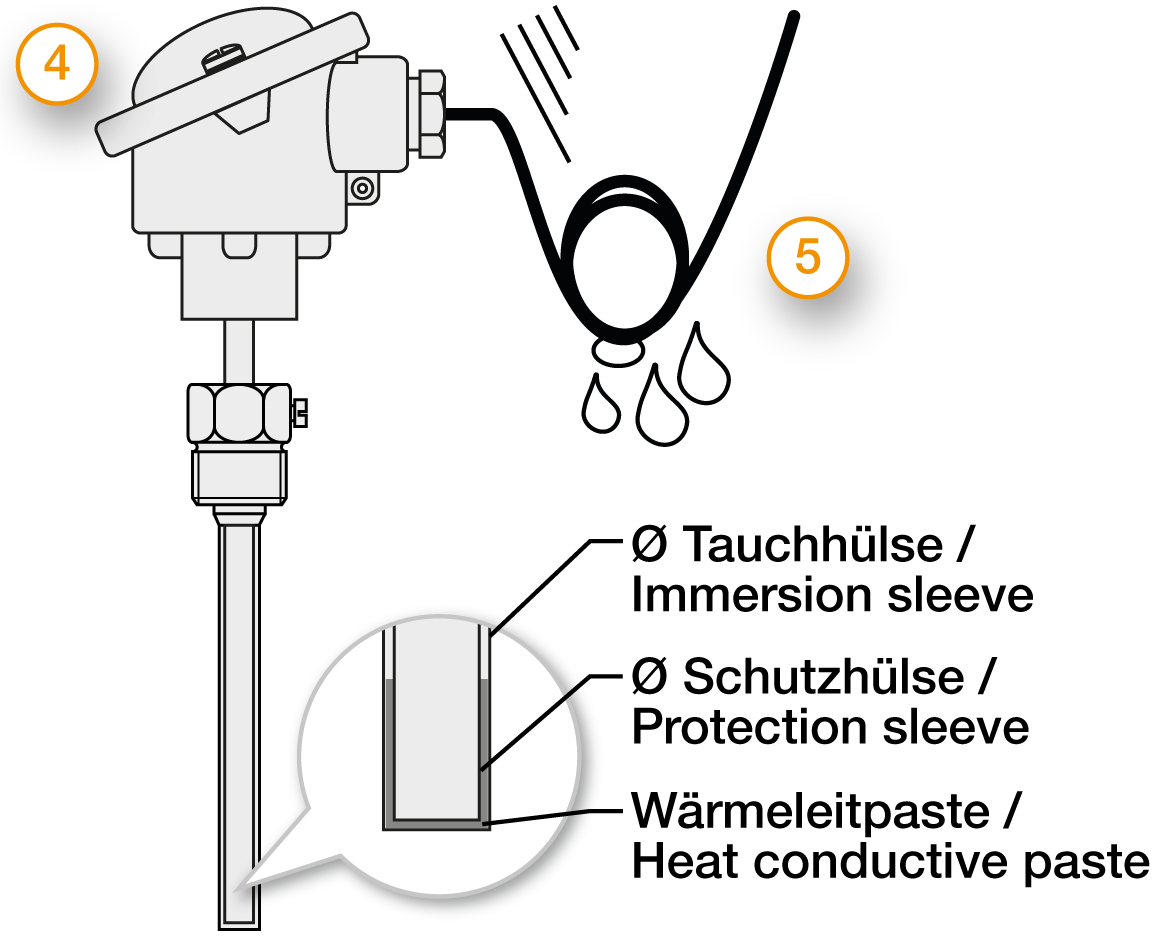

Immersion double thermocouple with head - Important assembly advices | |||||||||||||||||||

| Measuring errors can occur due to heat dissipation to the environment. To keep these as small as possible, we recommend immersing the thermowell of your temperature sensor as deeply as possible into the medium to be measured during installation. The optimum installation depth should be 10-15 times the Ø of the thermowell or, when using a thermowell, the Ø of the thermowell. When installing in pipelines whose Ø does not have a sufficiently deep installation depth, you should install the probe either at an angle or in a pipe elbow. Make sure that there is sufficient space for the sensor to be removed. 1) Installation with sufficient installation depth 2) Installation at an angle with small pipe Ø 3) Not like this: Minimum installation depth not reached | ||||||||||||||||||

| Installation by means of compression fitting: Please tighten the union nut of the compression fitting by hand as far as it will go (clearly noticeable). For compression fittings with PTFE pressure ring, please make a 1/4 turn with a wrench suitable for the width across flats. These compression fittings can be used several times in this way. In the case of compression fittings with stainless steel cutting ring, the compression fitting connects to the protection tube. This connection is pressure resistant up to 40 bar. However, the compression fitting can only be used once. It must also be tightened more firmly. Please tighten it with 1 3/4 turns. | |||||||||||||||||||

| Mounting by means of mounting flange: Please make sure that the Ø of the mounting flange matches the Ø of the protective sleeve. For B-head fittings or very long protection sleeves, we recommend a stainless steel or aluminum mounting flange due to its stability. | ||||||||||||||||||

| Mounting by means of immersion sleeve (4): Please note that the Ø and the length of the immersion sleeve must be selected to match the installation situation so that the minimum immersion depth can be achieved. Since the sensor is not inserted directly into the medium, but via the immersion sleeve, the response times are somewhat slower. The sensor should be selected so that the thermowell touches the bottom of the immersion sleeve and the air cushion around the thermowell is as small as possible. The use of thermal paste can improve the response times. | |||||||||||||||||||

| Please lay the cable with reserve loop (5) and in such a way that no water can penetrate the sensor head. This allows you to extend the sensor without disconnecting the electrical connection. | |||||||||||||||||||

Qualification measurement series to ensure the function of our temperature probes over their service life | |||||||||||||||||||

| Robust even with temperature changes | Temperature probes are exposed to harsh environmental conditions, such as changing temperatures and humidity, and should still work reliably in the field for 15 years or more. | |||||||||||||||||

| Resistant to heat and humidity | Extremely varying ambient conditions cause immense stress for the temperature probe and the design must be suitably robust and qualified. | |||||||||||||||||

| Long-term stable in any weather | Continuous exposure to sunlight, snow, fog, cold and ice shall not impair the function of the temperature probe and compliance with the specification. | |||||||||||||||||

| Robust even under high vibration load | Depending on the application, compressors and fans generate strong vibrations which are transmitted to components and cables. Therefore the used temperature probes have to be vibration resistant (20g). | |||||||||||||||||

| Reliable in practice: high pull-out force | The robust design ensures the necessary cable pull-out resistance, even under vibration and higher temperatures. | |||||||||||||||||

| Efficient through short response time | Depending on the application, short response times may be necessary to ensure efficient control of the system. Our sensor design is optimised for this requirement and we prove response times. | |||||||||||||||||

| Corrosion-resistant even in salt spray | Temperature probes are also used in coastal regions. For this reason, the temperature probes must also be able to withstand salty air for a lifespan of 15 years. | |||||||||||||||||

Applicable for this probe type | |||||||||||||||||||

| Thermocouple: | 2 x Type J Class 1 |

| Temperature range: | -40 °C to +750 °C |

| Connection head: | Form B |

| industry: | Glass industry, Machinery and apparatus engineering, Power generation, Steel and iron industry |

- Download Datenblatt Doppelthermoelement Typ J mit B-Kopf - T

- Download Bedienungsansleitung Doppelthermoelement Typ J mit B-Kopf - T

- Download Konformitätserklärung Doppelthermoelement Typ J mit B-Kopf - T

- Download Kennlinie Thermoelement Typ J

- Download Characteristic thermocouple type J

- Download Betriebsanleitung Thermoelemente

- Download Operating instructions Thermocouple