Prices incl. VAT plus shipping costs of 4,95 € to GER (incl. VAT)

Delivery time 4 Workdays to GER (AT, NL, BE +1 workdays)

Bitte stellen Sie sicher, dass die technischen Daten der Anschlussleitung, insbesondere hinsichtlich Temperatur und IP-Schutzklasse, zu Ihrer Applikation passen. Detailierte Informationen finden Sie in unseren Datenblättern.

Temperaturbereiche unserer Leitungen:

Glasseide: -50 °C bis +400 °C

Bitte beachten Sie den spezifizierten Temperaturbereich des Stecker / der Aderendenhülsen

isolierte Aderendhülsen: bis 80 °C

Mini-TE-Stecker: bis 220 °C

TE-Stecker: bis 220 °C

| E - Material connection cable: | ||

| F - Length connection cable: | ||

| G - Connector: | ||

| H - Bend protection: | ||

| Quantity: |

- Order number: 803181-3211

Advantages

- Advice directly from experts

- Quality directly from the manufacturer

- Long-term stable temperature probes over years

- B2B customers welcome: All information here

Our employee will be happy to help you:

Julian Mäntele

Tel.: +49 (0)7653 96 59 771

E-Mail: jmaentele@testo-sensor.de

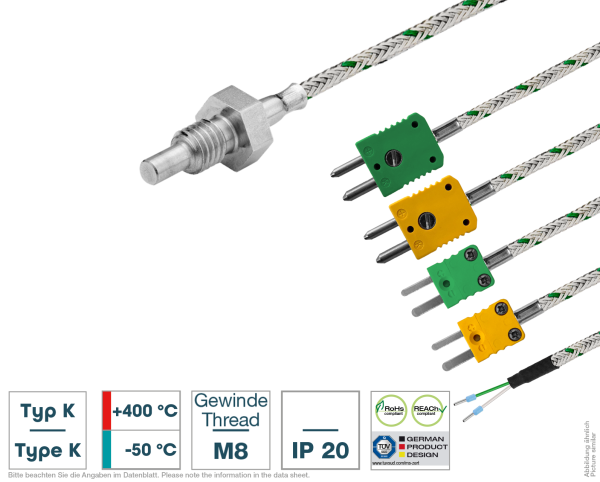

Screw-in thermocouples with glass fibre cables are shielded and measure the temperature in pipelines or vessels up to +400 °C. They are crimped and also have a poorer seal than other cables due to the insulation material used.

Here you can find our downloads for the Thermocouple type K M8 with glass fibre cable

Thermocouple M8 - General Information | |||||||||||||||||||

| Measuring range | -40 °C to +400 °C | ||||||||||||||||||

| Perm. °C range cable | -50 °C to +400 °C | ||||||||||||||||||

| Accuracy | -40 °C to +375 °C: ±1,5 °C | 375 °C to 1.000 °C: ±0,004 |t| according to DIN IEC 60584 Class 1 | ||||||||||||||||||

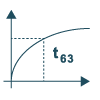

| Response time | t63 / t99: information is available on request | ||||||||||||||||||

| Pull-out force | ≥ 30 N | ||||||||||||||||||

Thermocouple M8 - Supply and output | |||||||||||||||||||

| Measuring element | Thermocouple Type K | ||||||||||||||||||

| Measuring point | Measuring point isolated | ||||||||||||||||||

| Measurement signal | Thermovoltage | ||||||||||||||||||

Thermocouple M8 - Ambient conditions | |||||||||||||||||||

| Protection class | IP20 according DIN 60529 (depending on cable) | ||||||||||||||||||

| Humidity and moisture condensation resistance | according to application-specific qualification | ||||||||||||||||||

Thermocouple M8 - Certificates and Standards | |||||||||||||||||||

| Standards | DIN EN 61326-1:2013 | DIN EN IEC 63000:2019-05 | ||||||||||||||||||

| Directive | RoHS 2011/65/EU | 2014/30/EU | ||||||||||||||||||

| Certificates | Certificate of suitability (on request) | ||||||||||||||||||

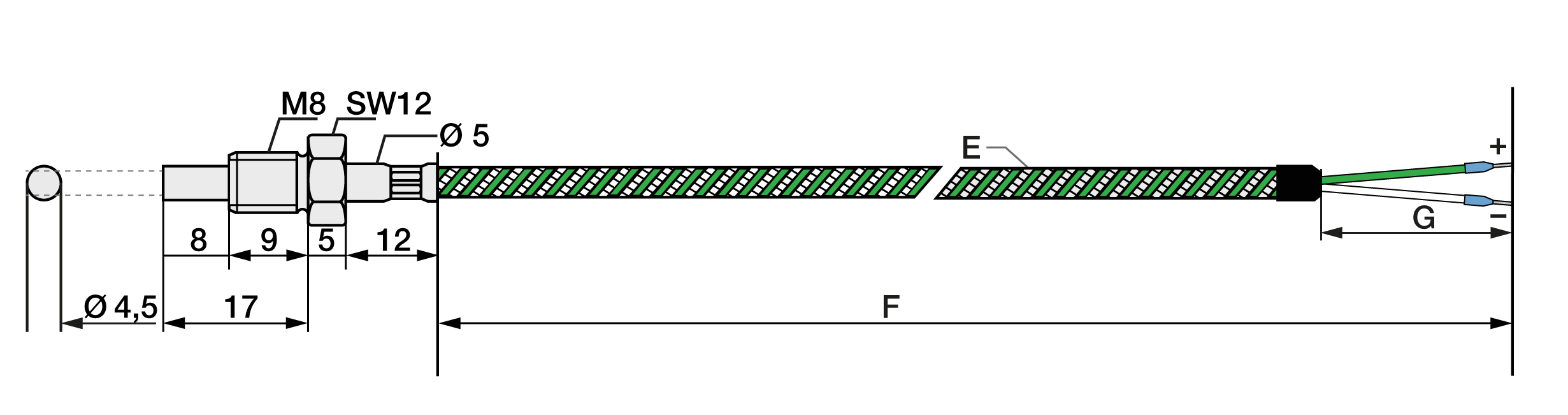

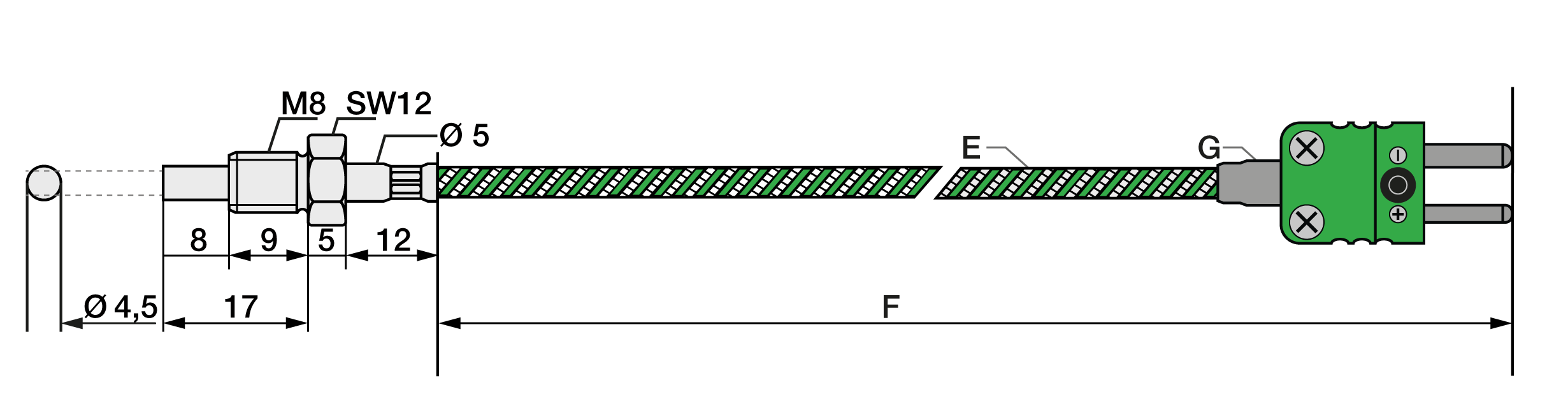

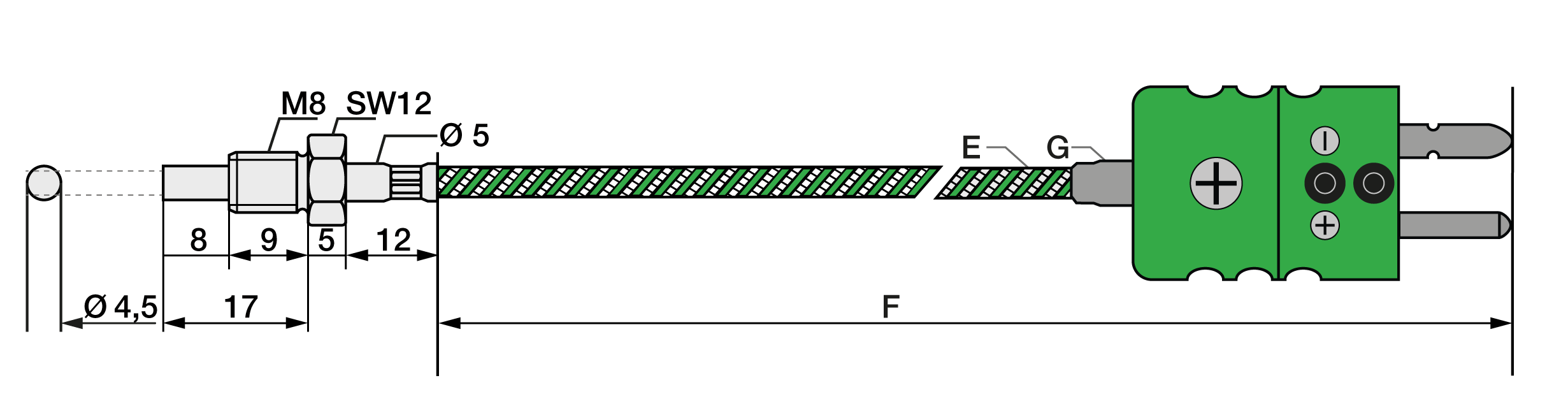

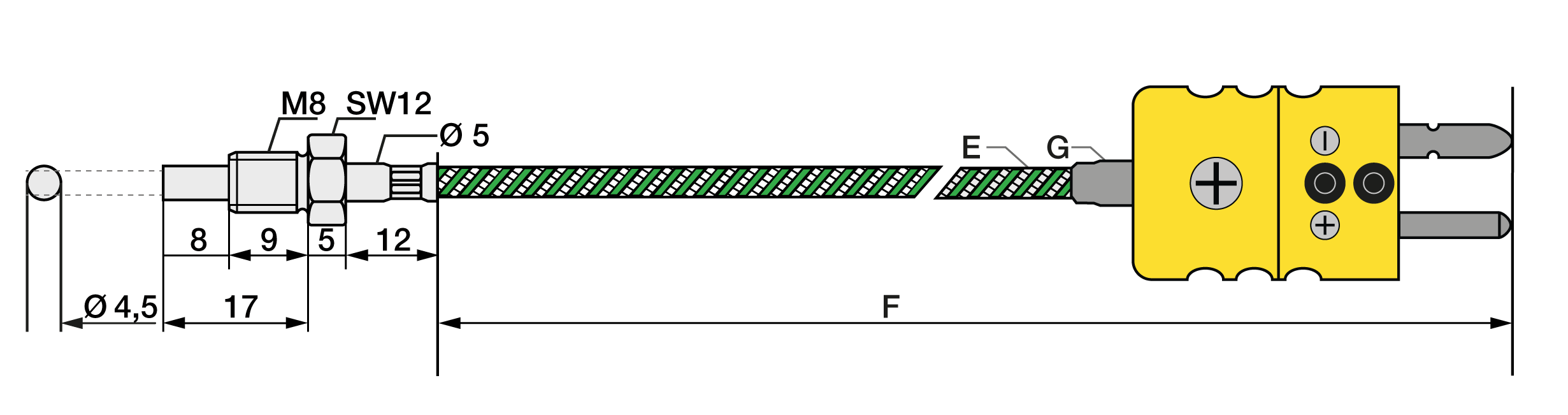

Thermocouple M8 - Technical Drawing | |||||||||||||||||||

| |||||||||||||||||||

| E - Material connection cable | |||||||||||||||||||

| |||||||||||||||||||

| F - Length connection cable | |||||||||||||||||||

| |||||||||||||||||||

| H - Bend protection | |||||||||||||||||||

| |||||||||||||||||||

| G - Connector | |||||||||||||||||||

| |||||||||||||||||||

| All dimensions in mm | |||||||||||||||||||

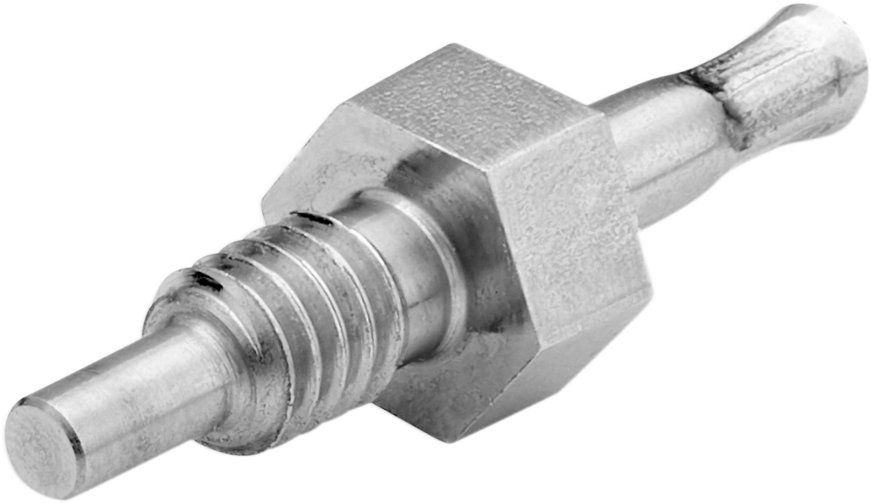

Thermocouple M8 - Screw-in thread | |||||||||||||||||||

| Thread | |||||||||||||||||||

| Material thread | Stainless steel 1.4301 | SUS 304 |  | |||||||||||||||||

| Length (mm) | 9 | ||||||||||||||||||

| Thread | M8 | ||||||||||||||||||

| Wrench size | 12 | ||||||||||||||||||

| Protection sleeve | |||||||||||||||||||

| Material | Stainless steel 1.4301 | SUS 304 | ||||||||||||||||||

| Diameter (mm)1} | 4,5 | ||||||||||||||||||

| Mounting length (mm) | 17 | ||||||||||||||||||

| 1} Tolerance ± 0,1 mm | |||||||||||||||||||

Thermocouple M8 - Thermocouple cable | |||||||||||||||||||

| Type | Color | Material (Outside / Inside) | Perm. range °C | Ø Outside (mm) | Cross section (mm²) | Color strand | Ω / m | |||||||||||

| Thermocouple cable | Type K1} | Glass fibre / Varnish | -50 to +400 | 3,0 ± 0,2 | 0,22 | gn, wt | 4,502} | ||||||||||||

| Length (m) | 1, 2, 3, 4, 5, 10, 15, 20 | ||||||||||||||||||

| Insulation resistance: ≥ 100 MOhm at min. 100 VDC | 1}Color according to IEC 584 | 2}per thermocouple | Cable available as accessory | |||||||||||||||||||

Thermocouple M8 - Connector | |||||||||||||||||||

| Insulated end ferrules (50 mm) | |||||||||||||||||||

| Mini-TC connector Type K gn | |||||||||||||||||||

| Mini-TC connector Type K ye | |||||||||||||||||||

| TC connector Type K gn | |||||||||||||||||||

| TC connector Type K ye | |||||||||||||||||||

Thermocouple M8 - Delivery | |||||||||||||||||||

| Assembly instructions | per process connection | ||||||||||||||||||

| Delivery and Packaging | Probe, seperatly packaged in PE bag | ||||||||||||||||||

| Matching accessories | Heat-conducting paste | ||||||||||||||||||

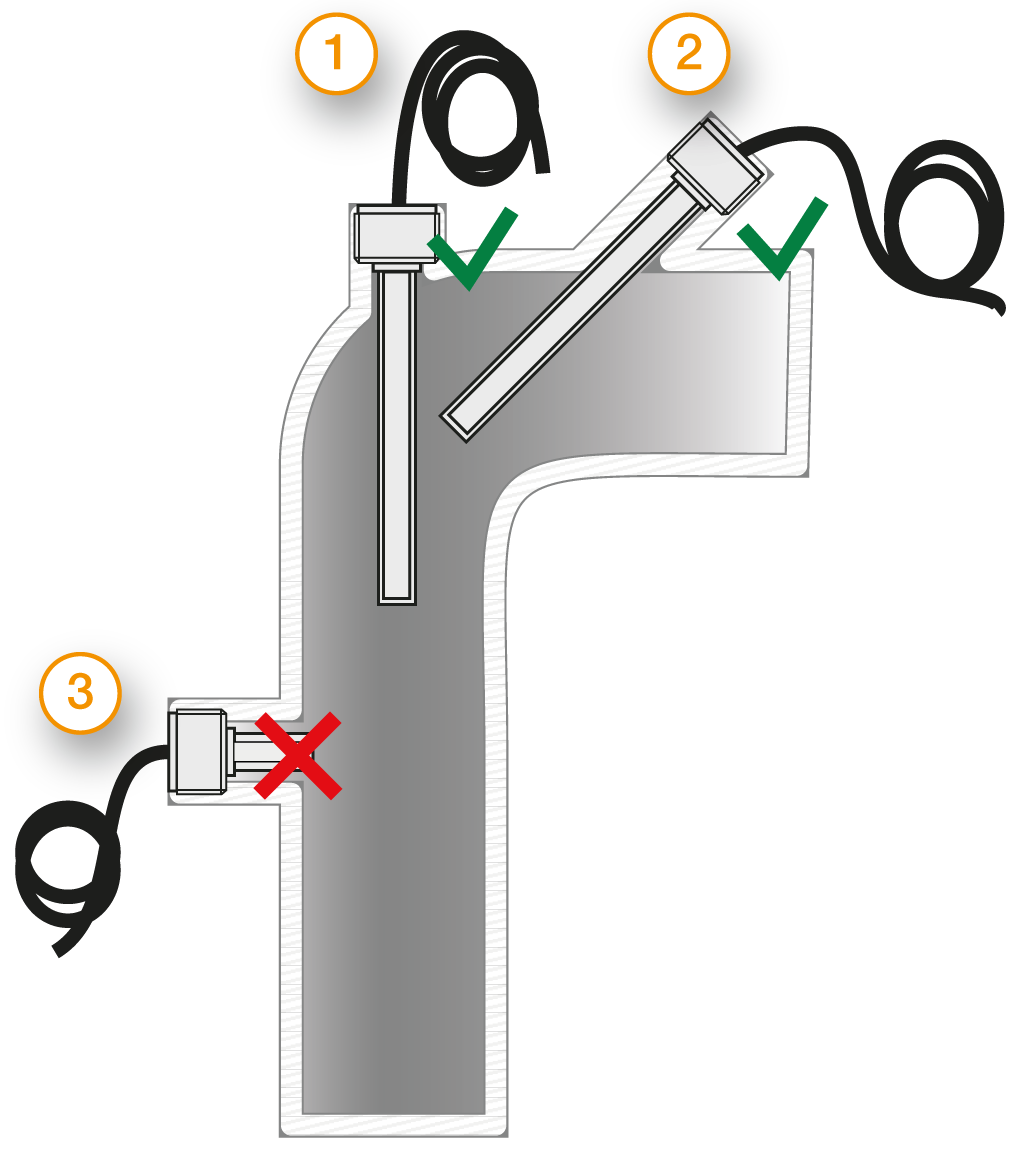

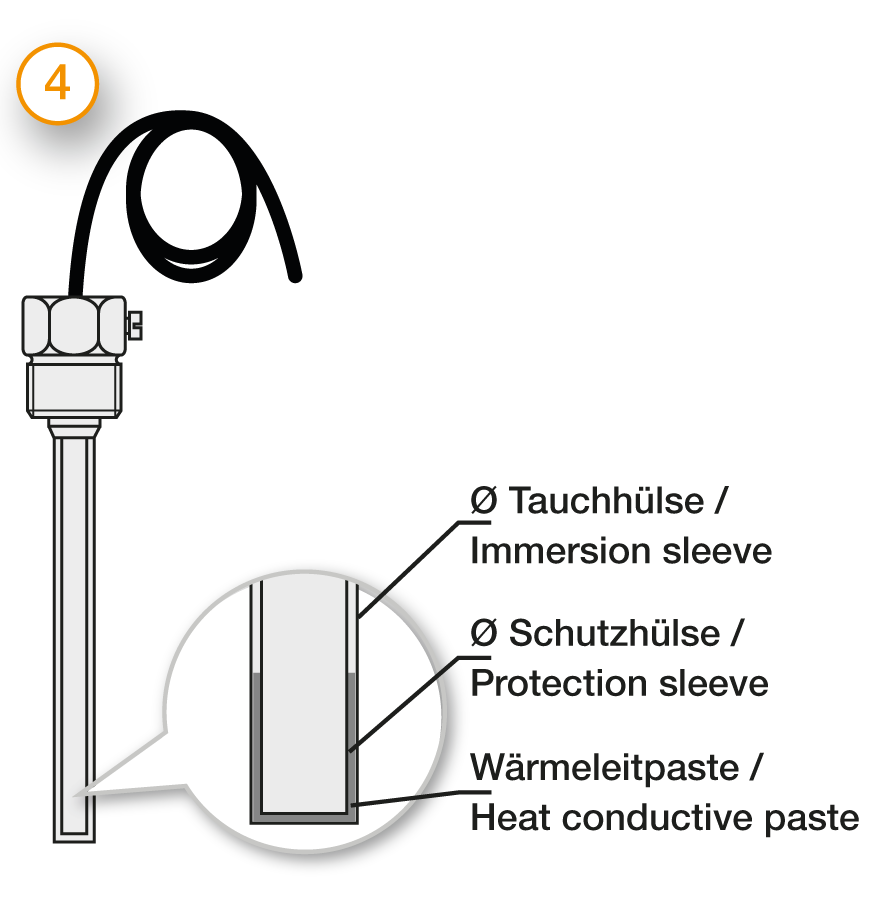

Thermocouple M8 - Important assembly advices | |||||||||||||||||||

| Measurement errors can occur due to heat dissipation to the environment. To keep these as small as possible, we recommend immersing the protection sleeve of your temperature probe as deeply as possible in the medium to be measured during installation. The optimum installation depth should be 10-15 times the Ø of the protection sleeve or, when using an immersion sleeve, the Ø of the immersion sleeve. When installing in pipelines whose Ø does not have a sufficiently deep installation depth, you should install the probe either at an angle or in a pipe elbow. Make sure that there is sufficient space for the probe to be removed. 1) Installation with sufficient installation depth 2) Installation at an angle with small pipe Ø 3) Not like this: Minimum installation depth not reached | ||||||||||||||||||

| Please lay the cable in such a way that no water can penetrate the probe and with reserve loop (4). This allows you to extend the probe without disconnecting the electrical connection. | ||||||||||||||||||

Qualification measurement series to ensure the function of our temperature probes over their service life | |||||||||||||||||||

| Robust even with temperature changes | Temperature probes are exposed to harsh environmental conditions, such as changing temperatures and humidity, and should still work reliably in the field for 15 years or more. | |||||||||||||||||

| Resistant to heat and humidity | Extremely varying ambient conditions cause immense stress for the temperature probe and the design must be suitably robust and qualified. | |||||||||||||||||

| Long-term stable in any weather | Continuous exposure to sunlight, snow, fog, cold and ice shall not impair the function of the temperature probe and compliance with the specification. | |||||||||||||||||

| Robust even under high vibration load | Depending on the application, compressors and fans generate strong vibrations which are transmitted to components and cables. Therefore the used temperature probes have to be vibration resistant (20g). | |||||||||||||||||

| Reliable in practice: high pull-out force | The robust design ensures the necessary cable pull-out resistance, even under vibration and higher temperatures. | |||||||||||||||||

| Efficient through short response time | Depending on the application, short response times may be necessary to ensure efficient control of the system. Our sensor design is optimised for this requirement and we prove response times. | |||||||||||||||||

| Corrosion-resistant even in salt spray | Temperature probes are also used in coastal regions. For this reason, the temperature probes must also be able to withstand salty air for a lifespan of 15 years. | |||||||||||||||||

Applicable for this probe type | |||||||||||||||||||

| Thermocouple: | Type K Class 1 |

| Temperature range: | -40 °C to +400 °C |

| Material cable: | Glass fibre |

| Process connection: | M8 |

| industry: | Automotive, Cement and building materials industry, Glass industry, Heating technology, Machinery and apparatus engineering, Plastics industry, Power generation, Steel and iron industry, Waste recycling/incineration |

- Download Datenblatt Thermoelement Typ K M8 mit Glasseide-Leitung

- Download Data Sheet Thermocouple type K M8 with glass fibre cable

- Download Bedienungsansleitung Thermoelement Typ K M8 mit Glasseide-Leitung

- Download Konformitätserklärung Thermoelement Typ K M8 mit Glasseide-Leitung

- Download Kennlinie Thermoelement Typ K

- Download Characteristic thermocouple type K

- Download Betriebsanleitung Thermoelemente

- Download Operating instructions Thermocouple